What Is Chicken Mesh for Plaster | Type of Chicken Mesh for Plaster | Why Use Chicken Mesh for Plaster

Table of Contents

What Is Chicken Mesh for Plaster?

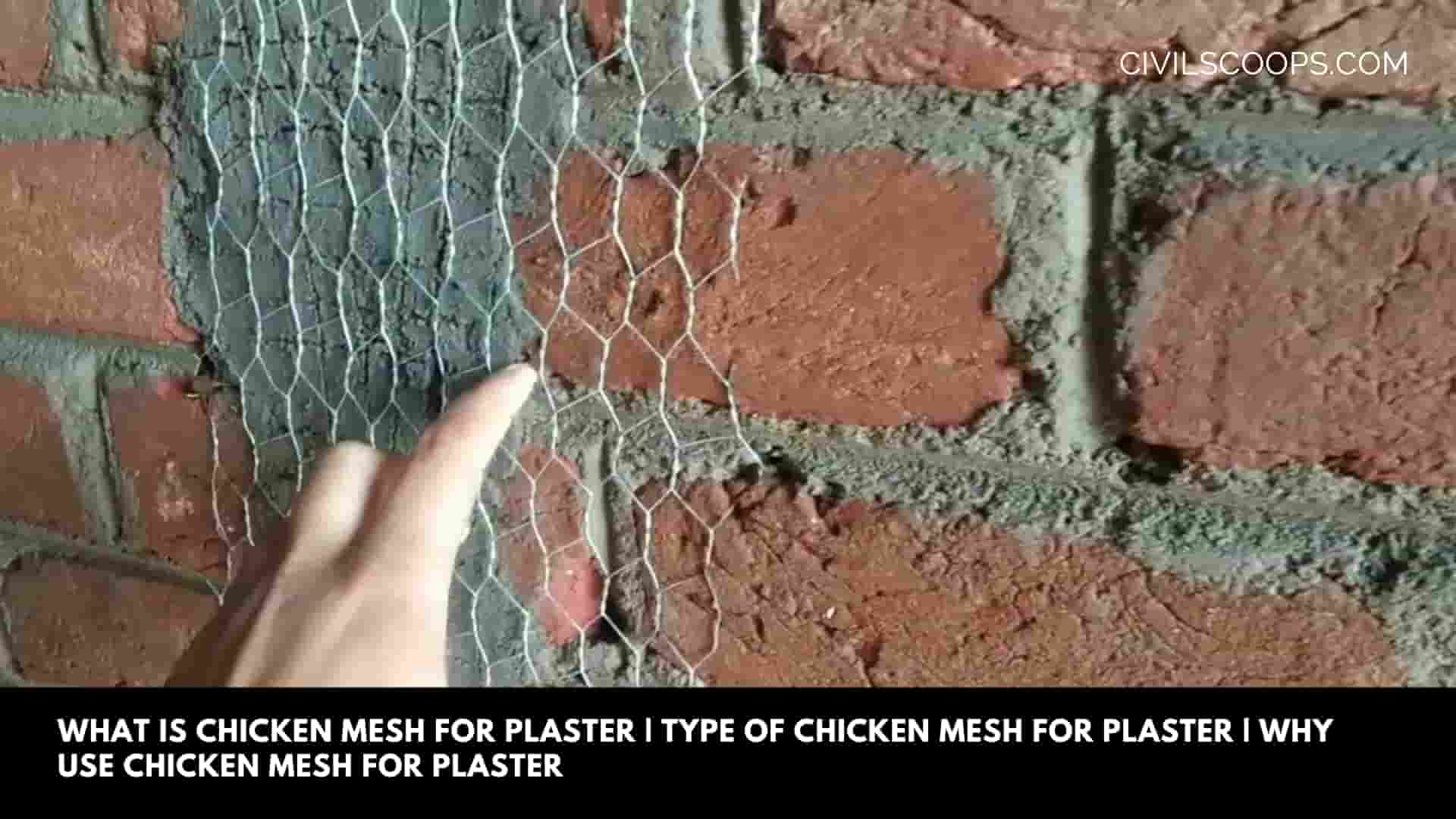

Chicken wire has specific properties for plastering use. Chicken wire mesh is formed by twisting two adjacent wires at least four times, forming a strong honeycomb mesh structure.

So, it has high strength and durability. Using it when plastering effectively prevents the plaster layer from drying out and cracking.

The hair cracks are mainly formed on the plastering layer. And mainly Hair cracks are often found on the column and brickwork joints. This happens because

Contraction and expansion for concrete occur more when compared to brickworks. Hence there’s a difference between these and thus forms the crack.

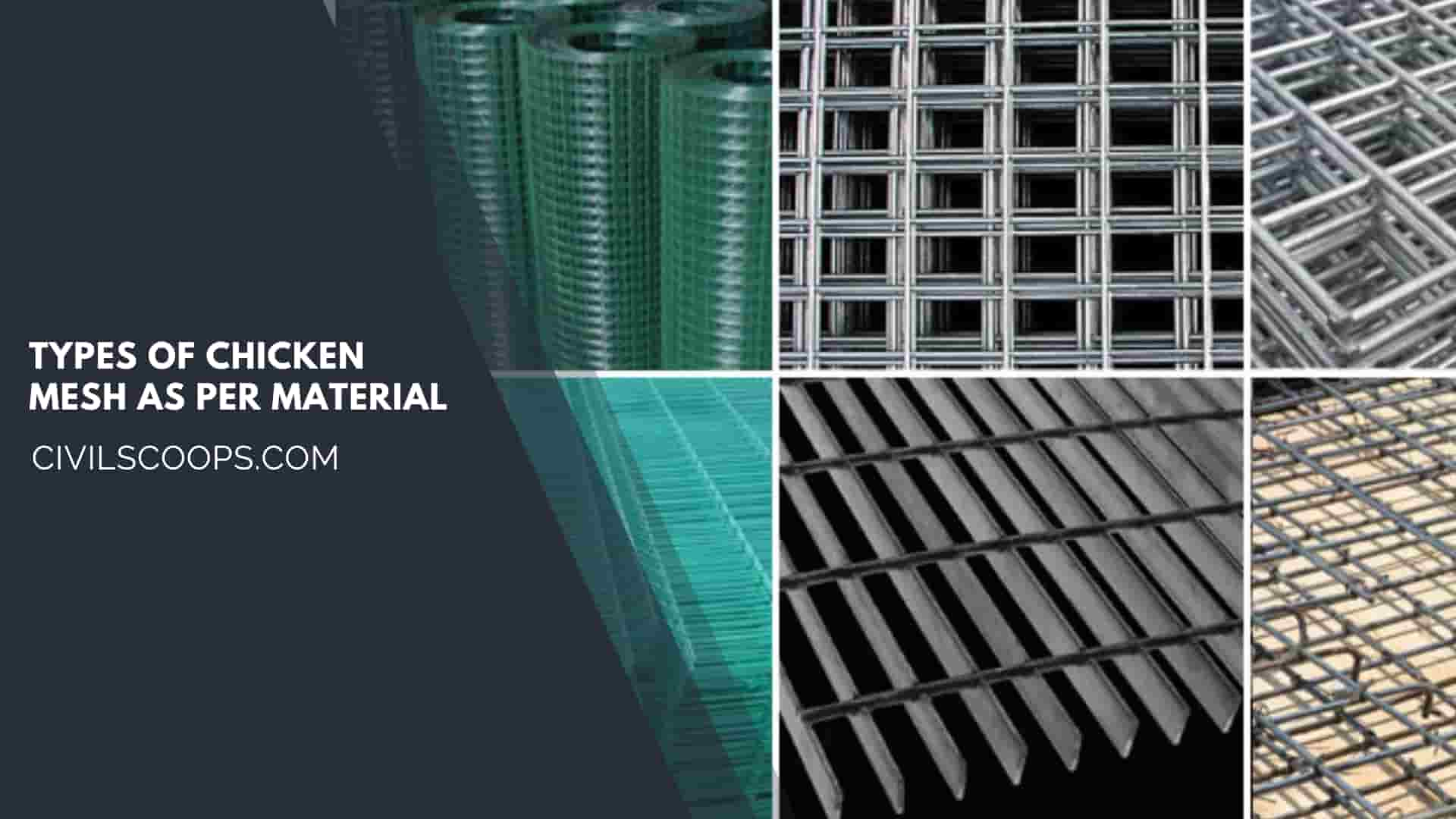

Chicken mesh for plaster material virus three different

Types of Chicken Mesh as Per Material

- Wier Mesh

- Fibreglass Mesh

- Plastic Mesh for Plastering

1. Wier Mesh

As per below, different types of wire mess like.

- Light Type Expanded Metal

- Plaster Chicken Wire

- Welded Wire Mesh

- Chain Link Mesh

1.1. Light Type Expanded Metal

The expanded metal used for plastering

The expanded metal mesh is mostly used as a reinforcing material for interior decoration, especially when plastering works, so sometimes referred to as stucco netting.

This is manufactured from a sheet steel blade, which cuts through and uniformly stretched at cells having a diamond shape.

So, it has no welds or bends, and is durable and very strong, with a low weight. This ribbed surface makes it has the max adhesion.

Each of these materials has its own disadvantages and advantages. But this best currently considered material is the light type expanded metal.

1.2. Plaster Chicken Wire

Small chicken wire mesh

The chicken wire mesh is formed by twisting both adjacent wires at least four times, creating a strong honeycomb mesh structure.

So, it has high durability and strength.

Its hexagonal shape prevents the formation of internal stresses.

Because of its flexible structure, chicken wire mesh is convenient for mounting on angled and curved surfaces. Its other benefits are twisted mesh, no risk of injury at work, and improved corrosion resistance.

As its mechanical properties and special physical, chicken wire is ideally suited for reinforcement plastering in construction, reinforcement waterproofing, leveling floors, and facade work.

1.3. Welded Wire Mesh

The welded wire mesh used for inside plastering work

The welded wire mesh is primarily made of thin, low-carbon drawn wire or galvanized wire with a dia. of 1.5mm to 0.4mm, located in mutually perpendicular directions and interconnected by spot welding.

Its wire dia. It is much smaller than this standard welded wire mesh. The welded mesh plastering has a wide scope. It may be used for the building outside and inside the plaster reinforcement.

If used for interior plasterwork and no corrosion material, needs no galvanizing, common carbon wire mesh will work well.

1.4. Chain Link Mesh

Chain link fence used as plastering mesh

The chain link Plastering mesh is a type of light chain link fence used to prevent wall cracks because of temperature changes.

This chain-link fence with its lightweight, thin wire from 2.0mm to 0.5mm and small mesh opening from 5mm to 25mm, is also called a mini or micro chain wire fence.

The man is plastering to a wall using a chain-link fence as support mesh Chain link fence used as plastering mesh.

Galvanized wire and low-carbon steel and are its main materials. Because the mesh for reinforcing the plaster surface doesn’t involve direct contact with the grid environment.

This is particularly important in the construction of industrial plants, in which these walls are exposed to high-vibration impacts as a result of these machines, presses, and other powerful mechanisms.

2. Fibreglass Mesh

Plaster fiberglass mesh protects the wall surface

Fiberglass mesh is a cheap material that doesn’t burn and is characterized by low weight and high strength.

These properties allow it to be successfully used in this formation of plaster facades, as well as used on ceiling surfaces and internal walls.

This material is widely used for fastening this surface layer in the corners of the room.

This most widely used standard fiberglass plater mesh is a density of 145g/m2 and 165g/m2 for facade work and exterior cladding.

The resistance to alkalis doesn’t decompose and will not rust over time, it doesn’t emit toxic and harmful substances, has a high resistance to tearing and stretching, protects this surface from cracking, and improves its mechanical strength.

3. Plastic Mesh for Plastering

Plastic mesh is used to plastering to a brick wall

The plaster plastic mesh for fast-drying dry mixes plastering Plastic mesh is recommended for plastering internally and externally.

Perform this function of protection against the formation and reinforcing mesh of surface crevices and cracks, increase its mechanical strength, and prevent deformation.

However, its scope isn’t limited to Plastering.

The plastic plaster mesh is also successfully used in painting works and plastering by pouring floors, for sound insulation and heat wall surfaces, for the reinforcement of door and window frames, and to protect the facades.

Especially recommended for plaster using fast-drying dry mixes, plastic mesh with large mesh is an alternative to metal plaster mesh.

Why Use Chicken Mesh For Plaster?

To prevent a crack in plastering work we use chicken mesh at the junction. Different materials such as between column and wall junctions where the coefficient of thermal expansion

Different material is different, and because of that, the chances of cracking after plastering is bound to occur, that’s why we use chicken mesh.

Chicken mesh has the same function as reinforcement does in concrete. It strengthens the plaster against forces.

Mainly to avoid the crack formed due to insufficient gap filling between the RCC column & Brick wall joint.

Therefore we used chicken mesh in plastering, and also due to this, there will be a proper bond formation between the finishing surfaces of the RCC column & Brick wall.

Chicken mesh in old plaster was used to prevent cracking and hold the plaster together should the house experience settlement.

The mesh also helps fight cracks caused by the twisting of plaster laths. Nowadays, I use galvanized wire mesh screwed to old wooden laths to protect my repairs against cracking.

In exterior plastering, you shouldn’t use chicken mesh if the plastering is thinner than 20 mm since the mesh is not galvanized enough and gives you a risk for rust expansion, and then the plastering will fall down before it’s due.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Chicken Wire Sizes

Available in 1 inch (about 2.5 cm) diameter, 2 inch (about 5 cm) and 1/2 inch (about 1.3 cm), chicken wire is available in various gauges–usually 19 gauge (about 1 mm wire) to 22 gauge (about 0.7 mm wire).

Chicken Mesh in Plastering

Chicken Mesh in Plastering uses to prevent cracks. Concretes have a property of expansion and contraction. It expands in heat and contract on cooling. The gap between RCC Structures and walls joint fills with fixing Chicken Mesh before plastering.

Use of Chicken Mesh in Plastering

Chicken Mesh in Plastering uses to prevent cracks. Concretes have a property of expansion and contraction. It expands in heat and contract on cooling. The gap between RCC Structures and walls joint fills with fixing Chicken Mesh before plastering.

Chicken Wire and Plaster

Chicken wire has specific properties for plastering use. Chicken wire mesh is formed by twisting two adjacent wires at least four times, forming a strong honeycomb mesh structure. So, it has high strength and durability. Using it when plastering effectively prevents plaster layer drying out and cracking.

Plaster Over Chicken Wire

Chicken wire has specific properties for plastering use. Chicken wire mesh is formed by twisting two adjacent wires at least four times, forming a strong honeycomb mesh structure. So, it has high strength and durability. Using it when plastering effectively prevents plaster layer drying out and cracking.

What Is Chicken Wire Made of?

It is commonly made of a thin and flexible steel. However, it is incredibly reliable and stands up well against the elements. This is due to it being galvanised steel. Galvanisation refers to the steel being coated in a protective zinc coating.

Can You Use Chicken Wire to Reinforce Concrete?

Materials such as chicken wire, stucco mesh, wire screening, expanded metal, fence wire or fiberglass cloth should never be used as primary reinforcement because their properties are too variable or they are not sufficiently strong. You cannot rely on these materials.

Is Chicken Wire Safe for Gardens?

Not only is chicken wire suitable for gardening, but it’s actually one of the best materials for fencing and pest control. This type of mesh can even help plants grow when used to create cloches, planter walls, trellises, tree guards, and garden arches.

Chicken Mesh Meaning

Chicken wire, or poultry netting, is a mesh of wire commonly used to fence in fowl, such as chickens, in a run or coop. It is made of thin, flexible, galvanized steel wire with hexagonal gaps.

How to Set Up Chicken Wire?

What Is Polypropylene Mesh?

Chicken Wire to Reinforce Concrete

Materials such as chicken wire, stucco mesh, wire screening, expanded metal, fence wire or fiberglass cloth should never be used as primary reinforcement because their properties are too variable or they are not sufficiently strong. You cannot rely on these materials.

How to Install Chicken Wire Fence for Dogs?

How To Install A Chicken Wire Fence For Dogs With The Wooden Panel Method: Step-By-Step Guide

- Plan your fence and take measurements.

- Mark the spots for fence posts and the gate.

- Cut the boards and fence posts.

- Dig holes and install the fence posts.

- Install the chicken wire.

- Attach the top and bottom wood panels.

How to Install Chicken Wire?

How to Attach Chicken Wire to Metal Post?

Unroll the chicken wire a few inches and slip the horizontal wires along the first or second column of chicken wire cells into the tabs on a metal T-post and pinch them closed with pliers — or staple across each horizontal wire down the first column of cells to fasten the wire to a wooden post.

How to Attach Chicken Wire to Wood Post?

You can use a staple gun for attaching the chicken wire to wooden posts, frames, doors or anything else made out of wood. This will make your job quicker and easier. Make sure to pull the mesh taut but don’t overstretch it when attaching to any material.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Bamboo Flooring | Bamboo Flooring Pros and Cons

- Types of Coffered Ceiling | What Is Coffered Ceiling | Coffered Ceiling Cost

- All About Retrofitting | What Is Retrofitting | Why Need Retrofitting | Advantages And Disadvantages of Retrofitting of Building

- Automation in Construction | Advantages of Automation | Applications of Automation | Where Are Use Automation in Construction Sector

- What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

[/su_note]

Originally posted 2023-03-19 11:21:18.