Detail of Beam Connection | Simple Framing Connection | Semi-Rigid Framing Connection | Rigid Frame Connection

Table of Contents

Detail of Beam Connection

Beams are connected to the main beams or into the columns.

The design of these connections is more important -since the failure of the connection is more catastrophic than the failure of the beam section.

In this chapter different types of a beam, and connections are explained

As discussed in IS: 800-1984 recognizes the following three types of steel framework construction, depending upon the type

- Simple Framing (curve I)

- Semi-Rigid Framing (curve III),

- Rigid Frame Construction (curve II)

- The typical moment-rotation curves for the three types of framing (or connections) are shown in Fig.

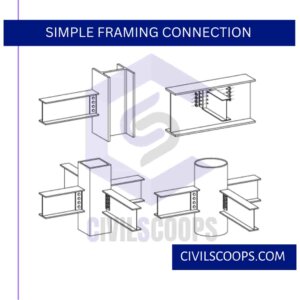

Simple Framing Connection

Simple framing is the one where rotational restraint at the ends of the members is as little as practicable, and in consequence, the structure may, for the purpose of design, be assumed as pin-connected.

For beams, simple framing provides only shear transfer at the ends.

The design of simply supported beams under the working stress method uses this type of connection, while simple framing is not used in plastic design.

One may consider the framing Simple if the original angle between intersecting pieces may change up to 80% of the amount it would theoretically change if frictionless hinged connections could be used

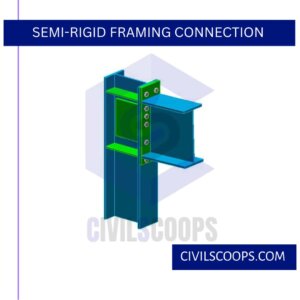

Semi-Rigid Framing Connection

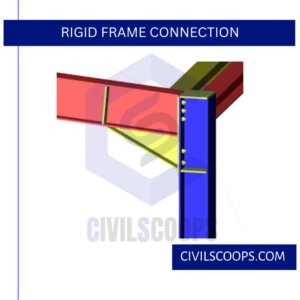

Rigid frame construction is the one where full continuity is provided at the connections so that original angles between the intersecting members are held virtually constant, i.e., with rotational restraint of the order of 90% or more of that necessary to prevent any angle change.

Such connections give the greatest rigidity and economy in the weight of steel used when applied in appropriate cases.

Such connections are used under both the working stress and plastic design methods.

Rigid Frame Connection

Semi-rigid framing is the one where rotational restraint is between 20 and 90% of that necessary to prevent any relative angle change. The semi-rigid connections develop less than the full moment capacity of the connected members.

With semi-rigid framing, the moment transmitted across the joint is neither zero (or a small amount) as in simple framing nor is it the full continuity moment as assumed in the elastic rigid-frame analysis.

Because of the difficulty of evaluating the degree of restraint, semi-rigid connections are not used in plastic design and are rarely used in working stress design.

Actual connections are neither completely rigid nor completely flexible and can be classified on the basis of the ratio of the moment developed by the connections to the full moment capacity of the connected member, expressed as a percentage.

As stated above, the approximate percentages for simple connections are from 0 to 20, for a semi-rigid connection from 20 to 80, and for a rigid connection from 80 to 90. The percentage of a particular connection must be determined by actual tests.

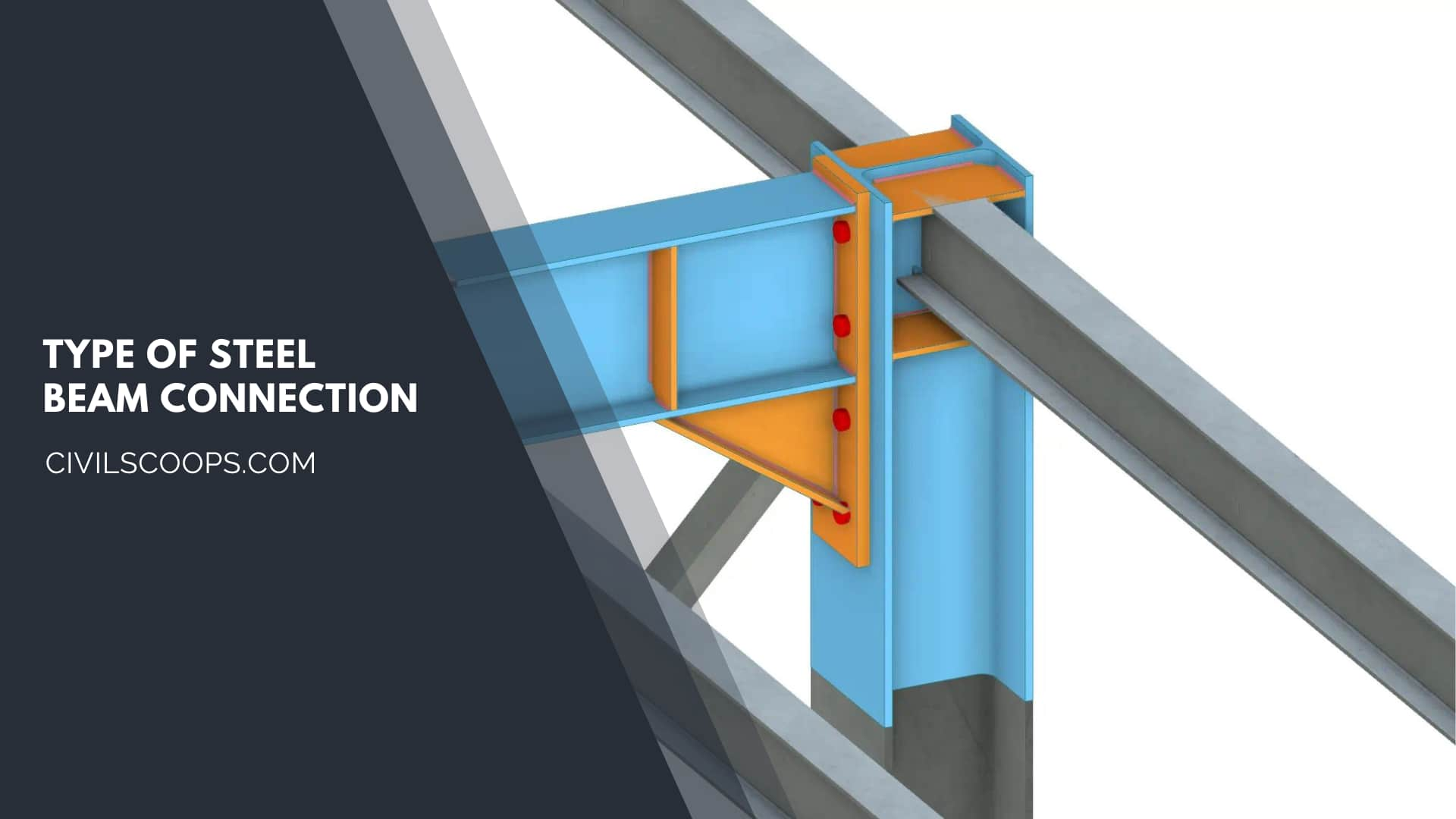

Type of Steel Beam Connection

- Riveted Beam Connection

- Bolt Beam Connection

- Welded Beam Connection

Riveted Beam Connection

-

Simple Beam Connections for Riveted

-

-

- Riveted Framed Connection

- Riveted Seated Connection

- Riveted Unstiffened Seated connection

- Riveted Stiffened Seated connection

-

- Moment Riveted Resistant or Rigid Connection

Simple Beam Connections for Riveted

Riveted Framed Connection

A framed connection is the one when a beam is connected to a girder or a stanchion by means of two angles placed on the two sides of the web of the beam, as shown below fig. no-1

Riveted Framed connection Fig No-1

When the beams intersect and are attached to other beams so that flanges of both are at the same elevation, as shown below fig. no-2 (a), (b), the beams framing-in have their flanges coped or cutaway.

Riveted Framed connection at the s

angle level Fig No -2

The loss of section is primarily loss of flange that carries little shear so that normally rope results in little loss of strength.

In framed connections, an angled shelf is sometimes used to support the connecting beam during the erection, simply to facilitate the process (as shown below fig. no-1), though the angled shelf is not an integral part of the connection and may be removed after the connection process is over. 3

Riveted Seated Connection

When a beam is connected to the flange (or the web) of a steel stanchion, the width of the flange (or the depth of the web) may be insufficient to accommodate the connecting angles. In that case, framed beam connections are not suitable, and seated beam connections are preferred.

In its simplest form, a seated connection is one in which a horizontal angle with its horizontal leg at its top is used to receive the beam on it, as shown in as per below fig; in such a case it is called an unstiffened seat connection.

Seated Connection

In addition to the seat angle, a web cleat is provided when the beam is connected to a beam (as per the above fig ) while a flange cleat is used when the beam is connected to a stanchion.

The angle cleats (i.e. web cleat or flange cleat) are essential parts of seated connections because they keep the beam stable in a vertical position and prevent it from lateral buckling.

When the reaction to be transferred by the beam is so large that the scat angle cannot support it, then the horizontal leg of the seat angle is stiffened by means of one or two stiffener angles, as shown in as per below fig.

StiffeSeated Connection

The stiffener angles should be tightly fitted under the seating angle and suitable packing should be provided, as shown in as per above fig.

Seated connections require more space in the vertical direction, and due to this, they are not commonly used for connecting the beam to a beam.

Seated connections are more suitable for connecting the beam to either the flange or to the web of a steel stanchion.

Similarly, a framed connection is not suitable for connecting a beam to the web of a column because of the space limitation on either side of the beam.

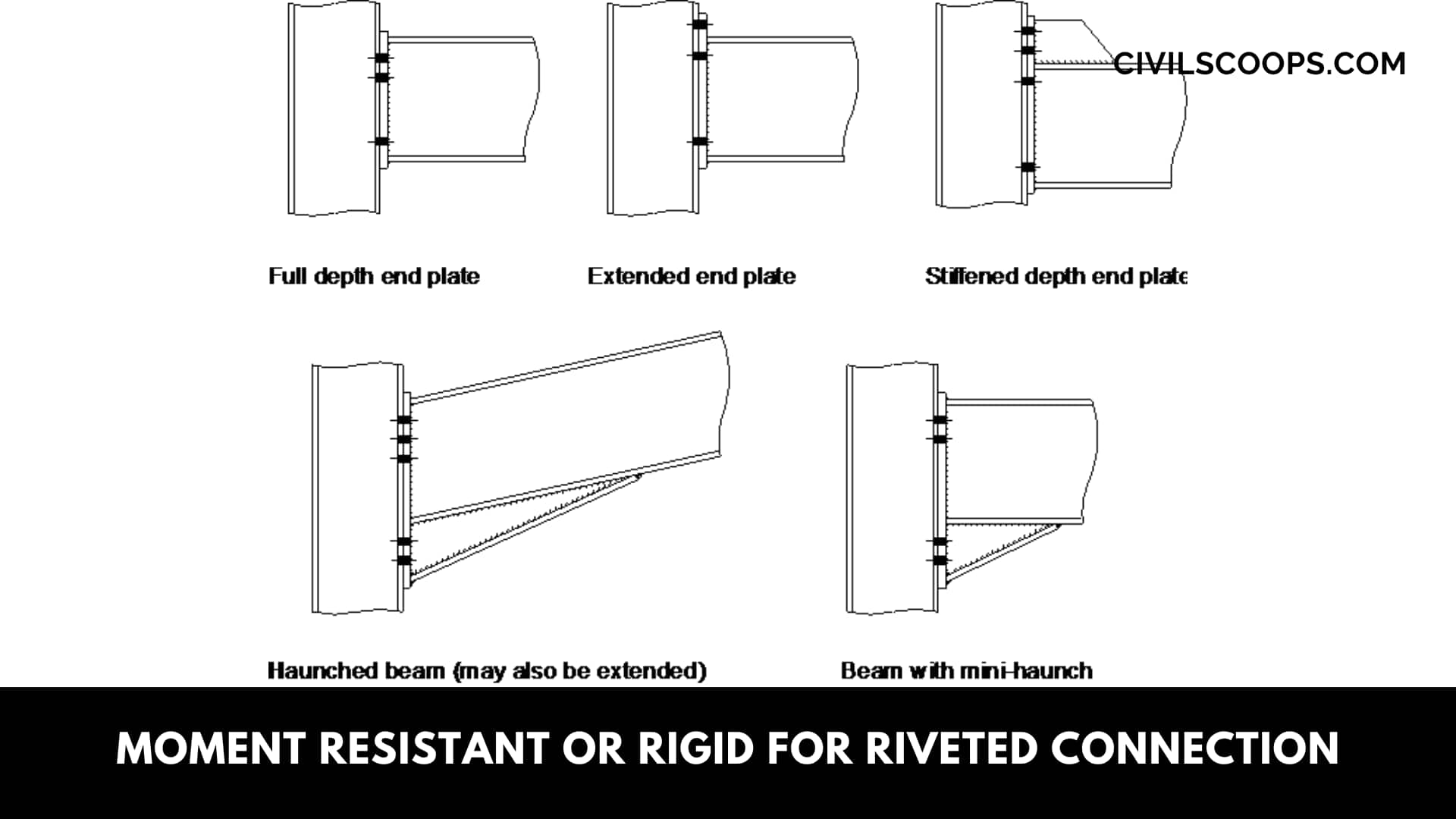

Moment Resistant or Rigid for Riveted Connection

Up to this stage, we have discussed simple connections that transfer shear only and permit full rotation of the beam.

Sometimes, it may be required to transmit moments also, in addition to shears, such as in building frames.

As discussed earlier, there are two types of constructions that permit the transfer of moments, either fully or partially:

- Rigid construction and

- Semi-rigid construction.

In both the above types of construction, the connections or joints are so designed that they permit the transfer of moment in addition to shear.

Based on the magnitude of the moment to be transferred, these may be two types of connections :

- Small moment resistance connections

- Large movement resistance connections

- Small moment resistance connections

- Large movement resistance connections

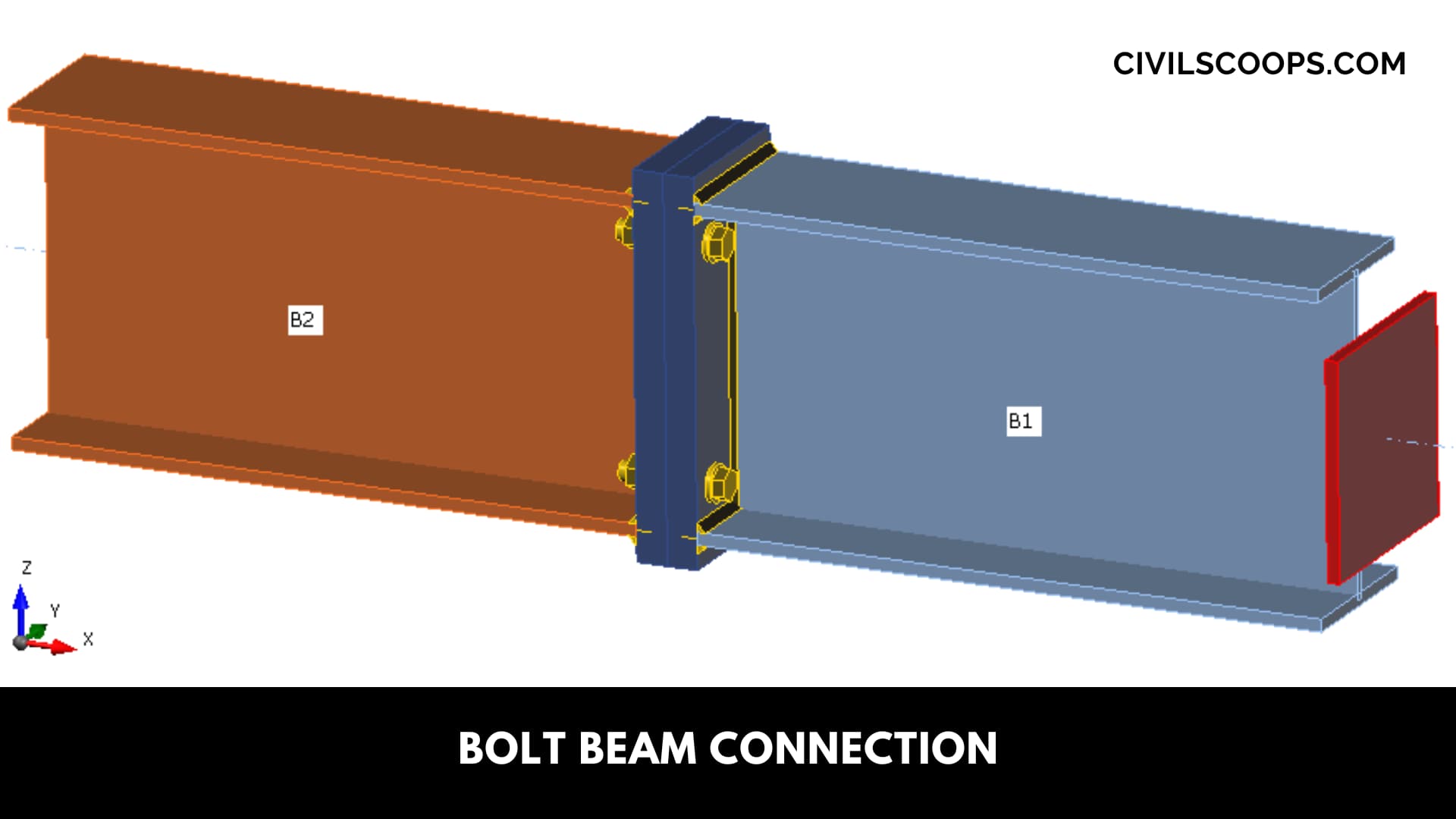

Bolt Beam Connection

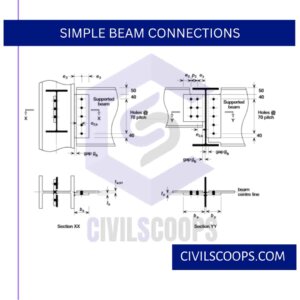

Simple Beam Connections

- Bolt Framed Connection

- Bolt Seated Connection

- Bolt Unstiffened Seated Connection

- Bolt Stiffened Seated Connection

Moment Resistant or Rigid for Bolt Connection

Simple Beam Connections

Bolt Framed Connections

When the end shear to be transferred is less, it is possible to connect the beam to the main beam or to the column using cleat angles, as shown in also shown in fig. (a) and (b).

Framed Connections

If the flanges of the beam to be connected are at the same level, the flanges of the connecting beam are cut, as shown below fig,

Framed Connections if flanges are at the same level

This will not pose any structural problem since at the end of simply supported beams moment is zero, and shear strength depends mainly on the strength of the web.

Bolt Unstiffened Seated Connection

When shear forces are larger, the depth of the cleat angle required for framed connection may be more than what can be provided at the available space.

In such cases of the seat, angles are connected to the column over which the beam rests.

At the top cleat, angles are provided to prevent the lateral displacement of the beam after positioning it over the seat angle also shown in below fig. a typical connection.

Unstiffened Seated Connection

Bolt Stiffened Seated Connection

If the shear force to be transferred at the beam is still large, the seat angle may fail.

To strengthen it, a stiffener angle can be provided, as shown in Fig. Such connections are known as stiffened seated connections.

Stiffened Seated Connection

Moment Resistant or Rigid Connection for Bolt

-

- Clip-Angle or Split Beam Connection

- Bracket Connection

- Clip Angle Connection

This type of connection may be used at the end of the moment to be transferred in the end is small as per below fig. shows a typical clip angle connection.

Clip angle connection

Split Beam Connection

Bracket Connection

If the moment to be transferred through this connection is large such connections are used as per below fig. shows a typical bracket connection.

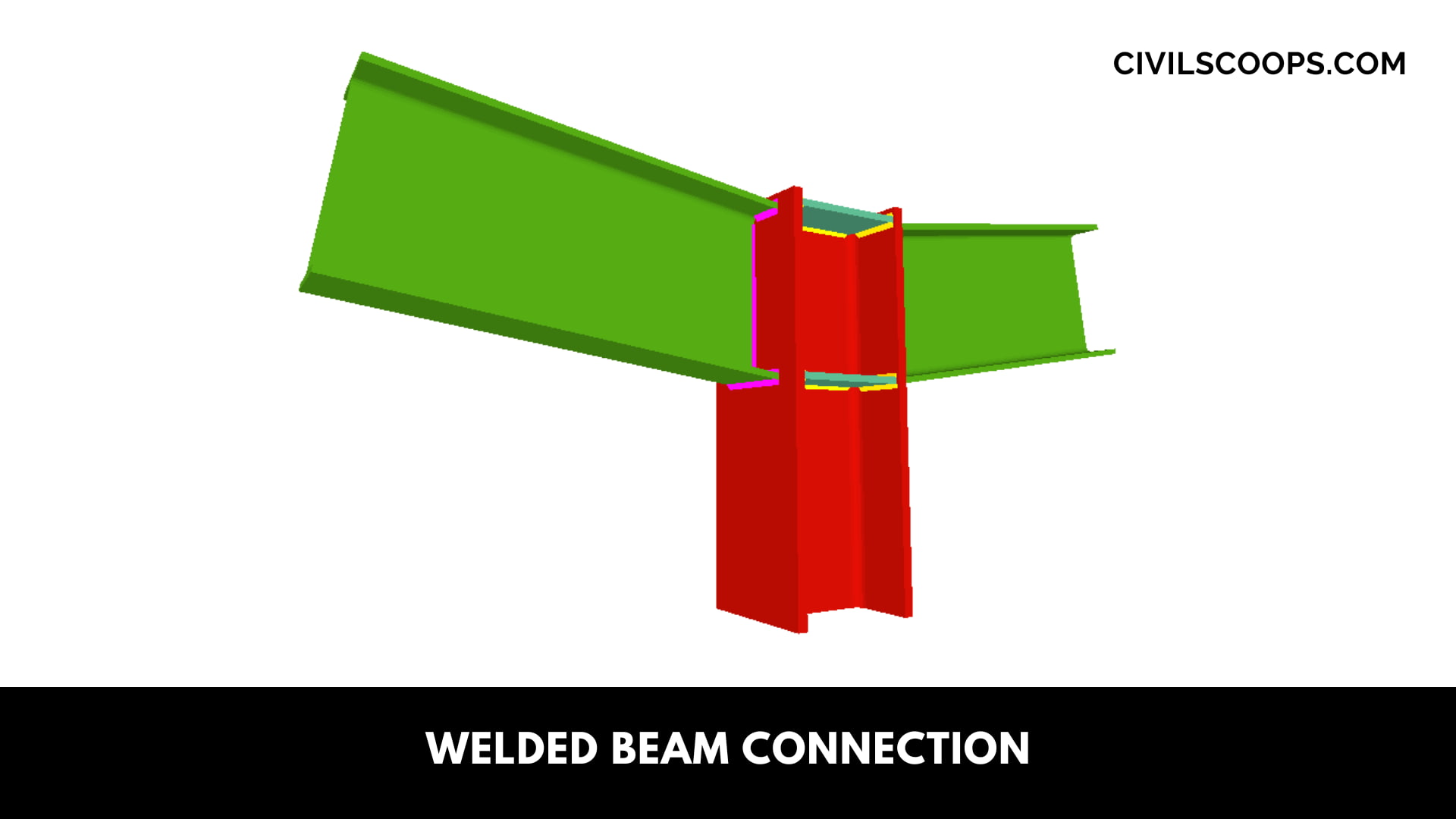

Welded Beam Connection

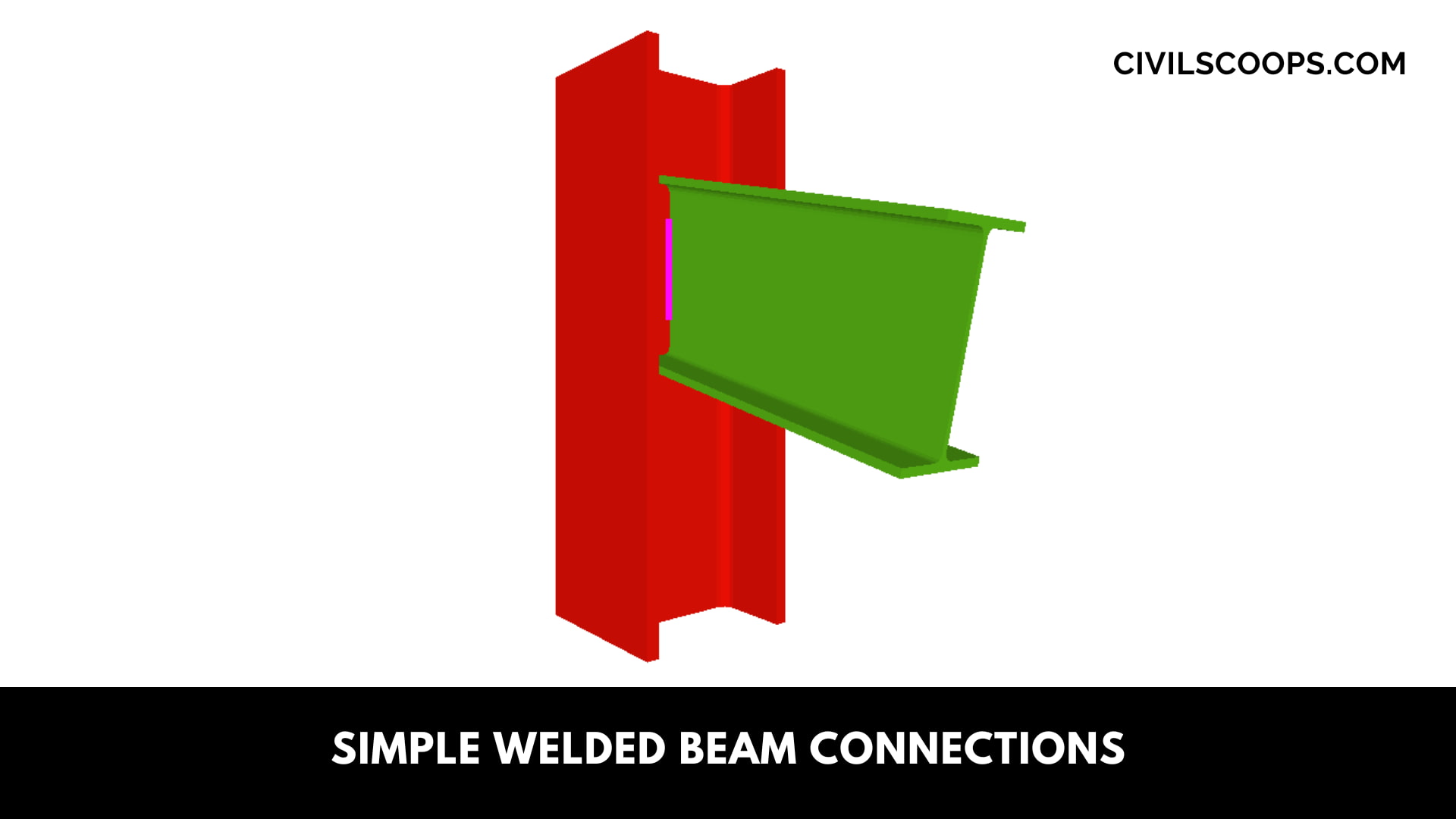

Simple Welded Beam Connections

- Beams may be connected to the supporting beam or to the supporting column by welding.

- In fact, welded connections are used more commonly instead of bolted connections.

- The end of the beam may be designed to transfer the only shear to the supporting structure by

- Framed connection

- Unstiffened seated connection

- Stiffened seated connection.

- The ends of the beam may be designed to transfer shear as well as moment by welded connection.

- Such connections are known as moment-resistant connections.

- In this chapter, the design of all such connections is explained

Moment Welded Resistant or Rigid Connection

Simple Welded Beam Connections

Welded Framed Connection

The direct fillet or butt welds explained need accurate lengths and edge finishes, which may be quite difficult to achieve.

Instead of these connections, framed connections may be adopted, which are flexible.

The following two types of framed connections are possible.

-

Double Plated Framed Connections

- Instead of two plates may be used for the connection beam and the supporting member to get more flexibility in the connection.

- The plate to are connected to the web of the beam by shop welding.

-

Double Angle Framed Connections

- Instead of two angles may be used for the connection beam and the supporting member to get more flexibility in the connection.

- The angles to are connected to the web of the beam by shop welding.

Double Plated Welded Framed Connections

Double Angle Framed Connections

Welded Unstiffened Seated Connection

When the end reaction to being transferred is low, welde unstiffened seat connection can be used. The beam is placed over a seat welded and angle

Welded Stiffened Seated Connection.

Welded Stiffened Seated Connection

As per a typical stiffened seat connection. The seat used can be a split two-plate, or I beam forming a T-section.

The seat plate thickness isn’t less than the thickness of the flange of the beam, and the thickness of the stiffening plate is not less than the thickness of the web of the beam.

Seat plates and stiffening plates are welded, as shown below, in Fig (a).

The width of the seat plate is kept equal to the width of the flange of the beam. The same size plate can be used as a stiffening plate.

Weld looks like a T-section, as shown below, in Fig. (b).

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Semi Rigid Connection?

A semi-rigid connection is a Type PR connection whose resistance to angle change falls somewhere between simple and rigid type. The spec provides for Type PR construction only in broad principals for analysis and design, therefore its left for the Engineer to implement the principals in a quantitative manner.

Rigid Connections in Steel Structure

Rigid connections are connections that do not deform significantly under applied moments. This means that have rotational restrained of 90% or more. In other words, it is provided full continuity at the connection.

Semi Rigid Connection

Semi-Rigid connections are designed to have some degree of rotational restraint and therefore will attract some moments. This means that the moment transmitted across the joint is neither zero, nor is it the full continuity moment as rigid connections.

Steel Beam Connections

In the framed steel beam connections, the beam is connected to the supporting steel element through fittings whereas in case of seated connections, the beam is positioned on seat similar to the case where beam is placed on masonry walls.

How to Join Steel Beams?

Joining steel beams together is usually done by bolting or welding. Buildings that are designed and erected using steel usually require steel members to be connected together in order to transfer forces. Bolting and welding are commonly acceptable methods of joining steel beams together.

Clip Angle Connection

Clip Angle connections are used for connecting a floor beam to another beam, or a column to a beam. The attached beam can be sloped to the main one. The angles are bolted or welded to the main beam.

Double Clip Angle Connection

A double clip angle connection is a connection consisting of two angles transferring the shear forces from one member to the next either through bolts or welds. The design of Double Clip Angle Connections is efficient and the connections themselves are easy to fabricate.

Stiffened Seated Connection

Stiffened seat connection

In this connection, the beam is supported on a seat attached to a supporting member and reinforced by the addition of a vertical stiffener. The stiffened seat is welded to the support and bolted to the supported beam.

Unstiffened Seated Connection

Unstiffened Seated Connections

Provide a clearance of 10 mm between the beam and the column. Compute the distance of end reaction from the critical section which is at the end of root of fillet from extreme fibre of flange. Calculate the bending moment M at the critical section xx.

Bracket Connection

Bracket connection

Brackets are projections that carry loads. The connection of a bracket to a support has to transmit both shear and moment. Fasteners or welds may be used for the purpose. Connections may be made with fasteners or welds subjected only to shear or to combined shear and tension.

Beam to Beam Welded Connection

A beam-to-beam connection is a welded joint between two beams. Typically, one beam acts more like a vertical column where the other protrudes horizontally off of it. This is a common structural support found in buildings and bridges. Often these are known as “cantilever beams”.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- All About Transom Window | What Is a Transom Window | Types of Transom Window

- Cantilever Bridge | Cantilever Bridge Advantages and Disadvantages | Cantilever Bridge Facts

- All About Tile Popping | What Is Tile Popping | Reason for Tile Popping | How to Fix Popped-Up Tiles

- What Is Plumbing Joint | 11 Types of Plumber Joint | Different Types of Pipe Joints and Where Are Use

- 20 Vastu Tips Before House Construction | Vastu Tips for Different Locations of House | Scientific Facts of Vastu Location of Rooms

[/su_note]

Originally posted 2023-05-02 05:50:17.