What Is Quarrying of Stones | Methods of Quarrying | Selection of a Site for Quarrying of Stones

Table of Contents

What Is Quarrying of Stones?

You must have heard the words mine and quarry. The operations of taking out the materials from the ground at great depths are known as mining, whereas in the case of the quarry, the operations for taking out the match (Stone) are carried out at ground level in an exposed condition.

The process of taking out stones from the natural rock is known as “quarrying” stones thus obtained are used for various engineering purposes.

Before discussing the methods of quarrying, let us discuss the natural bed and plane of cleavage, which play an important role in quarrying operations.

Natural Bed

The building stones are obtained from rocks. These rocks have a distinct plane of division along which the stones can be easily split-up. This plane is known as a “natural bed of stone.”

In stone masonry, the general rule to be observed is the direction of the natural bed should be perpendicular to the direction of the pressure, such an arrangement of stones gives maximum strength to stonework.

Natural beds of stone can be detected by pouring water and observing its fall in the direction of layers. Which respect to natural beds, stones for different work are placed in different situations as follows. In stone arches, the stones are placed with their natural beds in a radial manner.

Stone in case of cornices, string courses, etc.Should be placed in the vertical direction of natural beds. Stones of building walls should be placed horizontally in the direction of their natural beds.

Plane of Cleavage

Some rocks possess planes of stratification or cleavage. The rocks can be easily split along these planes. All sedimentary rocks have a distinct layer of stratification or cleavage. They are called stratified rocks.

Considerations for Quarrying of Stones

After the site selection, some important considerations are to be followed before starting the quarrying of stones.

Which are as follows:

The rock surface should be properly checked for cracks and fissures. The presence of these may cause planes in the stones, along which they may split. Then, the quarrying will be easy and quick as well as economical.

- The layout should be prepared, which contains different stages involved in the quarrying operation.

- The machines used should be tested to operate them easily and quickly.

- If the top surface of the site contains soft soil, then it should be removed and dumped.

- The removal of stones should be done carefully, otherwise, there may be chances of landslides or slips, which can cause severe damage to the lives of laborers.

Methods of Quarrying

Following are the common methods of quarrying

- Digging.

- Heating.

- Wedging.

- Blasting.

1. Digging

In this method, stones are merely excavated with the help of suitable instruments. This method is useful when soft stones occur at low levels in the ground.

2. Heating

In this method, the top surface of the rock is heated. Due to unequal expansion, the upper layer of the rock separates out and is indicated by a dull bursting noise.

The detached blocks are then removed. This method is useful when the rock formation consists of horizontal layers at shallow depth.

3. Wedging

If the rock surface contains cracks of fissures, this method is adopted. Steel wedges or points are driven through such cracks by means of a hammer.

Blocks of stones are then shifted, and they are removed with the help of suitable instruments. If natural cracks are not available, artificial cracks are formed. This method is adopted for rocks that are comparatively soft.

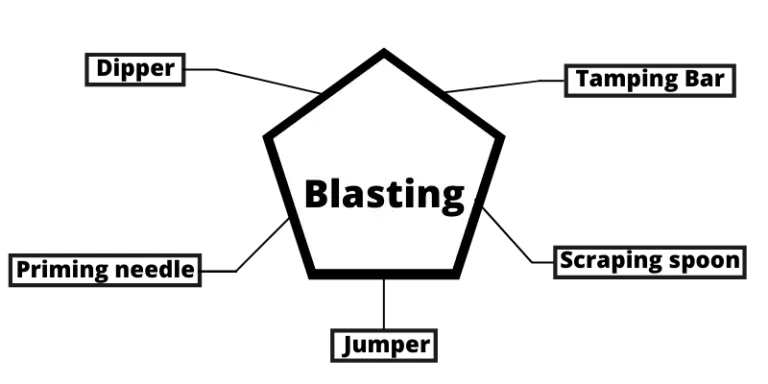

4. Blasting

Explosive is adopted in this method of quarrying to convert rocks into small pieces. This method is used when hand rocks having no fissures or cracks are to be broken down into small pieces.

Stone obtained by blasting is usually of small size, and they are used as ballast in railway, aggregate for concrete road metal. Etc. The following tools are required in the process of blasting. Dipper, Jumper, Priming needle, Scraping spoon, and Tamping bar.

The following materials are required in the process of blasting.

- A detonator is in the form of a copper cylinder, closed at one end. It contains 6 to 9 gm of culminating mercury. It is used when dynamite is used as an explosive and is fired either by a fuse or an electric spark.

- Explosives are adopted and are generally blasting powder and dynamite. Blasting powder is also known as gun powder. It is a

a mechanical mixture of charcoal, saltpeter, and sulfur. - Dynamite consists of 25% sandy earth saturated with 75% of nitroglycerine. It is in the form of a thick paste.

- Fuses are required to ignite the explosives. They are in the form of cotton rope with a core of continuous thread of fine gun

powder.

Selection of a Site for Quarrying of Stones

- Available tools, materials, and labor.

- Transportation facilities.

- Geological data.

- Quality of stone

- Quantity of stone

- A clean water source should be available near the quarry site.

- The site should be far from permanent structures like bridges, dams, etc. because the vibrations due to blasting in the site may

cause harm to them. - The non-living area should be available to dump the refuse obtained in quarrying.

- A proper drainage facility should be available.

- Geological information on the site should be read.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Methods of Quarrying

- Digging or excavating.

- Wedging.

- Heating.

- Quarrying with Channeling Machine.

- Blasting.

Quarrying Process

The development of most modern rock quarries involves stripping the overlying soil and weathered rock to get to the hard rock underneath. This is then worked in a ‘bench’ system, removing the rock in layers that can be returned year after year as the quarry is developed.

Quarrying of Stones

The method of removal of stones from their natural bed by using different operations is called quarrying. Methods of quarrying include a) Digging – This method is used when the quarry consists of small & soft pieces of stones.

Hadspen Quarry

Hadspen Quarry is a stone quarry in Somerset, England. It is shown on Ordnance Survey maps for 1888–90 and may have been in operation for a considerable period before that. It supplies natural stone walling throughout the West Country. The products include coursed, coursed random, and random rubble walling.

World’s Deepest Granite Quarry

ROAC maintains the world’s largest “deep hole” granite quarry. The quarry is called the “E. L. Smith Quarry”, and the Devonian Barre Granite is mined there.

Marble Quarries in the World

In countries around the world, stone and marble play an enormous role in the construction of buildings and statuary. Some of the most famous quarries in the world are located in Carrara in Tuscany, Italy; Portland Quarry in England; Paros and Pentellic Quarries in Greece and Rutland Quarry in Vermont, U.S.A.

Redstone Granite Quarry

Redstone is an unincorporated community within the town of Conway in Carroll County, New Hampshire, United States. It is located on the road from Center Conway to North Conway at the base of Rattlesnake Mountain.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Civil Engineering Basic Knowledge

- What Are the Components of Stairs | 19 Different Types of Stairs Components?

- Difference Between Heartwood and Sapwood | What Is Sapwood | What Is Heartwood

- 10 Different Between Mortar And Concrete | What Is Mortar & Concrete | Types of Mortar & Concrete

- Types of Bearing Capacity Failures of Foundation | Bearing Capacity Definitions | Theory of Terzaghi’s Bearing Capacity

[/su_note]

Originally posted 2022-09-07 13:07:49.