What Are Defects in Painting | 18 Types of Defects in Painting | How to Prevent Defects in Painting

Table of Contents

What Are Defects in Painting?

Painting is one of the important finishing works used in structural construction in Civil Engineering. Painting creates a coat-like formation that prevents attacks from various atmospheric factors like cold, heat, frost, rainfall, etc. But there are also some defects which are found in painting, those defects are-

Types of Defects in Painting

Types of Defects in Painting are as follows.

- Fading.

- Peeling and Blistering.

- Running.

- Grinning.

- Sagging.

- Chalking.

- Flaking.

- Blooming.

- Brush Marks.

- Drying is not proper.

- Efflorescence.

- Low Coverage.

- Wrinkling.

- Flashing.

- Alligatoring.

- Mildew.

- Patchiness.

- Loss of Gloss.

1. Fading

In painting work, fading is a common type of defect which causes discoloration on the paint. Rain, sunlight, frost, etc are the main causes of fading effects in painting.

In technical terms, fading is a process where that paint loses one or more color pigments. After a long time, the paint starts losing pigments to the effect of continuous sun exposure and harsh atmospheric condition.

Causes of Fading:

- Ultraviolet radiation, sunlight, and infrared radiations are one of the most important causes of fading.

- Coastal and harsh environments are the cause of fading.

- Temperature variations are the cause of fading.

- Inadequate film thickness and the use of dark colors are the cause of fading.

- Using low-quality paint is also a cause of the fading defect.

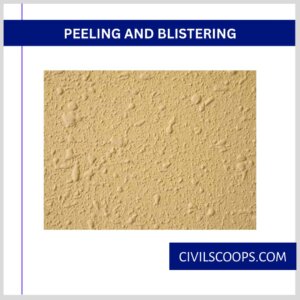

2. Peeling and Blistering

Peeling and blistering are the types of effects where the cause of that effect is swelling of that film. Due to moisture, oil, and grease, bubbles are formed in the film of the paint, this is the actual cause of this effect.

Swelling is happened due to excessive use of oil material on the final coat and inappropriate seasoning of timber.

Causes of Peeling and Blistering:

- High humidity and excessive moisture are the cause of Peeling and blistering.

- Lack of surface preparation and excessive layers of paint is one of the main causes of this defect.

- Poor quality paint, high temperature, and long exposure to sunlight are other causes of peeling and blistering.

- Inappropriate application techniques also cause peeling and blistering defects.

3. Running

When the surface of the paint is too smooth then the running defect occurs. In this type of defect, due to the excessive smoothness of paint sometimes it turns back to an uncovered position of the surface.

Causes of Running:

- Low viscosity is the main cause of the running defect.

- Excessive glossy surface is another cause of running.

- Irregular spray action and too-wet paint are also the causes of running defects.

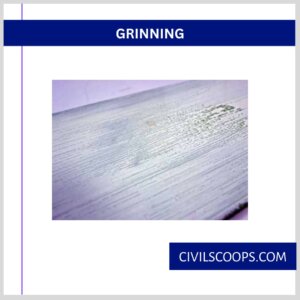

4. Grinning

When the required thickness of the paint is not provided then the backgrounds become visible, this action is termed a grinning defect.

Another type is the opacity of the final coat of paint is the cause of the grinning defect.

Causes of Grinning:

- The insufficient volume of the paint is the cause of the grinning effect.

- The inadequate thickness of the final coat is another cause.

- Low opacity of paint and uses of strong color in lower coats are causes of grinning defects.

5. Sagging

When a thick layer of paint is applied on a vertical or inclined surface then the layer is a gown downwards. This defect is called sagging.

Causes of Sagging:

- Poor workmanship and the excessive thickness of the paint coat are the causes of sagging.

- Inappropriate spraying techniques and low viscosity are the causes of the sagging defect.

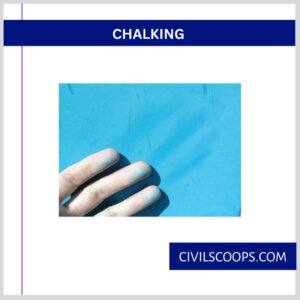

6. Chalking

In this type of defect, the material is converted into powder forms. The main cause of this effect is insufficient use of oil material.

Causes of Chalking:

- Long exposure to sunlight and ultraviolet radiation is the main cause of the chalking effect.

- Lower quality also causes chalking.

- The right use of thickness and alternate variation of weather is other main reason for chalking defects.

7. Flaking

In general, flaking is the defect where the paint de-touches the ground surface. This is mainly happening when the paints are not attached to the surface properly.

The weaker bond between the surface and the film of paint is the main reason for flaking.

Causes of Flaking:

- If you do not clean the surface properly then flaking defects happen.

- Poor adhesion of paint is the cause of flaking.

- The tendency of holding moisture is also the reason for flaking defects.

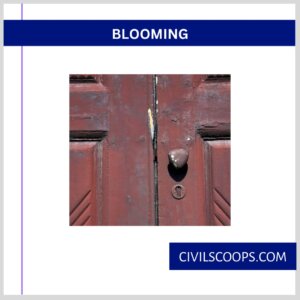

8. Blooming

The formation of dull patches on the surface is termed blooming. It creates a whitish patch on the whole surface of the paint.

After consolidation, water is collected from the body, nut that time some materials are started to go from the paint to water, and that effect causes the white patch on the paint.

Poor quality of paint and improper ventilation is the main cause of blooming defect.

Causes of Blooming:

- The excess humidity level is the main cause of blooming.

- Using fat-thinner materials is also the main cause of blooming defects.

- Poor workmanship and high air pressure are other causes of blooming.

- Poor ventilation and the use of low-quality paint are also the major causes of blooming defects.

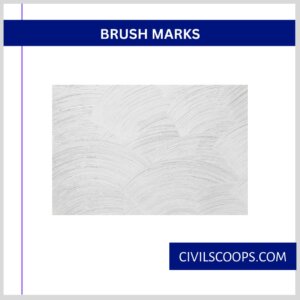

9. Brush Marks

Paint Brush marks are usually visible on the final coat. When the paint is applied on the surface with a brush, sometimes bristle marks appear. These bristle marks are deep and permanent on the painted surface.

Causes of Brush Marks:

- If you have the proper paint and tools, one of the key causes of brush marks is the paint dries too fast before it has time to flatten out.

- Painting in excessive heat speeds up drying and amplifies the possibility of brush marks. Next, the paint must not be too thick.

10. Drying Not Proper

If paint remains soft, tacky, or even wet for a long time, possible causes are application in unsuitable conditions, e.g. poor ventilation, low temperature, excessive humidity, chemical pollution, or application to surfaces on which there is grease, oil, wax polish, or similar contaminant.

Causes of Drying Not Proper:

- This problem happens when doing improper preparation, using a low-quality primer or no primer at all, using latex paints, applying a second coat too soon, or painting when there is a lot of humidity, cold weather, or poor ventilation.

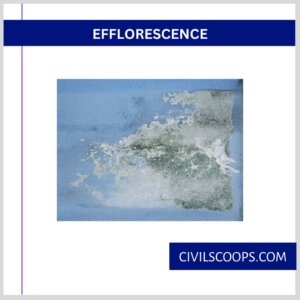

11. Efflorescence

Efflorescence” is the term most commonly used to describe the deposit of crusty white mineral salts that appear on a masonry surface (concrete, render, brick or mortar) that have leached out from within the substrate when moisture migrates through it.

Causes of Efflorescence:

- Efflorescence is caused by moisture ingress.

- This then reacts with carbon dioxide in the air to form insoluble calcium carbonate.

- As the moisture enters and moves through the wall or floor, it dissolves mineral salts present in the cement.

12. Low Coverage

If the paint doesn’t have good coverage, it’s a baffling experience. Conceal your wall with high-quality paint and cure common mistakes.

Causes of Low Coverage:

- Paint applied too thick or too wet to a vertical surface and the force of gravity overcomes the forces resisting the downward flow of paint (viscosity).

- Temperature too low to enable proper solvent evaporation (solvent-born paint), or humidity too high (waterborne paint).

13. Wrinkling

Paint wrinkling is a rough, crinkled paint surface, which occurs when uncured paint forms a “skin”.

Causes of Wrinkling:

- Applying paint too thickly (this is more likely when using alkyd or oil-based paints)

- Painting during extremely hot weather or cool damp weather, causes the paint film to dry faster on top than underneath.

- Exposing uncured paint to high humidity levels.

14. Flashing

Flashing is when light reflects against a freshly painted surface to create a shimmering “flashing” effect.

Causes of Flashing:

- A drywall patch wasn’t textured to match the rest of the wall.

- A quality primer wasn’t used first over freshly applied or textured drywall.

15. Alligatoring

Alligatoring paint is paint that has cracked in a pattern that resembles an alligator’s scales. When a top coat of paint is applied over an undercoat that is not completely dry. when a rigid substance, such as alkyd enamel, has been applied over something more flexible, such as a latex primer.

Causes of Alligatoring:

- When a top coat of paint is applied over an undercoat that is not completely dry.

- When a rigid substance, such as alkyd enamel, has been applied over something more flexible, such as a latex primer.

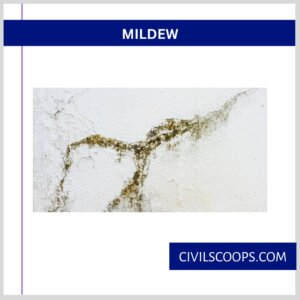

16. Mildew

Mildew is a fungus (mold) that grows on many exterior painted surfaces, as well as on interior bathroom walls and other humid or poorly ventilated interior areas. If not corrected, mildew will continue eating the existing paint away, causing eventual paint failure in the affected areas.

- Causes of Mildew:

Porous latex (water-based) paints without a mildewcide applied over a primer coat with linseed oil will develop severe mildew in warm, damp climates. - Mildewcides are poisons for mildew fungi. The paint label should indicate if a mildewcide is present in the paint.

17. Patchiness

Patchiness is when the paint does not present a uniform color and smooth appearance. The thickness and intensity of the film vary in different portions of the wall.

Causes of Patchiness:

- Not enough paint is applied or paint is applied unevenly, causing inconsistency in the film build and appearance.

- The topcoat is applied over spot-puttied surfaces.

- Painting over a highly alkaline surface, which is usually evident in new walls.

- The putty is not fully dry.

18. Loss of Gloss

A gradual loss of gloss is to be expected as a finish age. Early loss of gloss may be caused by applying paint or varnish in unsuitable conditions, e.g. low temperature or high humidity, or to surfaces on which there is grease, oil, wax polish, or other contaminants.

Causes of Loss of Gloss:

- Paint sinkage.

- Excessive film thicknesses.

- Wrong amount of hardener.

- Poor or incorrect paintwork care.

How to Prevent Defects in Painting?

The following is a list of Prevent Defects in Painting.

- Prevention of Fading Effect.

- Prevention of Peeling and Blistering.

- Prevention of Running.

- Prevention of Grinning.

- Prevention of Sagging.

- Prevention of Chalking.

- Prevention of Flaking.

- Prevention of Blooming.

- Prevention of Brush Marks.

- Prevention of Drying is not proper.

- Prevention of Efflorescence.

- Prevention of Low Coverage.

- Prevention of Wrinkling.

- Prevention of Flashing.

- Prevention of Alligatoring.

- Prevention of Mildew.

- Prevention of Patchiness.

- Prevention of Loss of Gloss.

1. Prevention of Fading Effect:

- The selection of lighter color paint is the first prevention of fading effect.

- You need to use a curtained UV-resistant paint from an authorized dealer.

- Regular and proper maintenance and supervision are the main prevention of fading defects.

2. Prevention of Peeling and Blistering:

- The first step of this work is cleaning the whole space and all the furniture is covered properly for the prevention of peeling and blistering.

- The second step is the peeling area of the surface is scrubbed with a wire brush for preventing this defect.

- Now it’s ready to prepare for new coats of paint.

- After that, the new primer coat is applied and at last, the main coating of paint is applied like this process the prevention of peeling and blistering happens.

Also Read: How to Calculate Steel in RCC Slab

3. Prevention of Running:

- At first, we need to keep our patience for the time required to be dried for the prevention of running defects.

- Then, you need to remove the run sandpaper or carbon block for preventing the running defect.

- The surface must be finely polished for prevention.

4. Prevention of Grinning:

- At first, the grinned surface must be cleaned properly for grinning prevention.

- Then you use another coating of paint to prevent the grinning defect is the prevention of grinning defect.

5. Prevention of Sagging:

- If the paint is in the wet condition it is rolled with a roller or brush but if the paint is in dry condition then we need to use sandpaper for sagging prevention.

- The paint should not be carried in cold conditions, these may prevent the sagging defect.

6. Prevention of Chalking:

- Using light shades of paint are the main prevention of chalking defect.

- You need to use water-based paints to avoid the chalking defect.

- Regular maintenance and inspection are the major prevention of chalking.

7. Prevention of Flaking:

- First, you need to clean the surface.

- Then the surface is rubbed with sandpaper for preventing the flaking effect.

- After that, the primary coat is applied to prevent the flaking defect.

- Finally, the surface coat is applied to prevent the flaking defect.

8. Prevention of Blooming:

- Using good quality paint, thinner, retarder, etc is one of the most important preventions of blooming defects.

- The temperature must be maintained at 68 degrees F to 78 degrees F for prevention.

- To prevent the blooming defect you need to reduce the air pressure.

9. Prevention of Brush Marks:

- Apply paint under the recommended viscosity using the correct thinner.

- Apply the paint quickly and evenly.

- Use clean and high-quality brushes.

10. Prevention of Drying Not Proper:

- Always apply in a dry, warm climate with sufficient air circulation.

- Ensure proper cleaning of the surface.

- Add cobalt and lead drier.

11. Prevention of Efflorescence:

- To prevent efflorescence, remove all powdery substances and thoroughly clean the surface.

- Ensure that the surface is moisture-free, clean, and suitable for the application of paint.

- Make sure joints and cavities are properly sealed.

12. Prevention of Low Coverage:

- Use latex primer for drywall, and oil-based for wood.

- Use a larger brush/roller.

13. Prevention of Wrinkling:

- Avoid painting in very hot, very cold, or very humid weather. Heat and humidity affect drying times, resulting in problems like wrinkled paint.

- Apply several thin, even layers of paint, rather than one thicker layer to obtain a smooth, wrinkle-free finish.

- Allow each layer of paint to dry before applying the next coat.

14. Prevention of Flashing:

- Use drywall primers (PVA).

- Keep the roller frame in the same direction.

- Paint large W on walls or ceilings.

- Inspect roller for paint build-up.

- Cleaning roller during the painting process.

15. Prevention of Alligatoring:

- Apply a high-quality primer before repainting.

- Make sure each layer of primer or paint dries completely before applying another coat.

- Be sure not to apply a rigid substance over a more flexible one.

16. Prevention of Mildew:

- For better mildew resistance and overall performance, choose 100% acrylic latex paint rather than vinyl acrylic paint.

- Contact our paint professionals for any questions you may have about mildew and which paints are best for preventing the growth of fungi.

17. Prevention of Patchiness:

- Use more paint and apply it to smaller sections.

- Allow new walls to cure thoroughly.

- For already painted surfaces, scrape off old paint and prepare the surface correctly.

- Fill cracks in plaster with cement sand mixture If you’re applying spot putty, follow it up with a coat of primer.

18. Prevention of Loss of Gloss:

- Use epoxies in warmer drier conditions where possible.

- Follow recommendations provided by the paint supplier.

- Topcoat finishes, especially two-pack polyurethanes, can be affected by early evening dew or mist.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Defects in Painting

Paint & Coating Defects: What Are The Common Types?

- Abrasion. Removal of a part or whole of the paint or coating film caused by impact by an object harder than itself.

- Adhesion Failure.

- Blistering.

- Bloom / Blush.

- Chalking.

- Cissing.

- Cracking.

- Cratering.

Fish Eyes in Paint

What are Fisheyes and What Causes Them? One issue that may occur on a paint job is called “fisheye.” Fisheyes (also known as craters) are an unattractive occurrence that can happen when dirt, wax, oil, or silicone gets stuck under the paint on your car. This causes spots or bubbles in the paint job.

Cissing Paint Defect

This is caused by painting over contaminated surfaces such as wax, oil or polish. The paint cannot adhere to the surface and draws away leaving unpainted areas. Allow the surface to dry and then rub down using ‘wet and dry’ abrasive paper and a solution of warm water and detergent.

Auto Paint Defects Examples

List of Common Auto Detailing Paint Defects:

- Swirl Marks or Spider Web Swirls.

- Marring.

- Micro Marring.

- Buffer Trails and Holograms.

- RIDS (Random Isolated Deep Scratches)

- Bird Droppings a.k.a. “Bird Bombs”

- Bird Drop Etchings.

- Light Water Spots.

Paint Defects and Solutions

Painting Defects that occur during or immediately after the application of paint on walls

[su_table responsive=”yes” alternate=”no”]

| Paint Defect | Remedies |

| Crawling | 1. Ensure to have a sand, dirt or dust free surface. 2. Remedy materials such as Polyether modified polydimethylsiloxane (PDMS) or non-ionic surfactant for water borne paints can also be used. |

[/su_table]

Paint Defects

- Brush Marks.

- Chalking.

- Sagging.

- Drying not proper.

- Efflorescence.

- Peeling.

- Flaking.

- Low Coverage.

Paint Defects Blistering

Blistering is described as the formation of bubbles that range in various sizes and elevations within the coating. These bubbles can be broken or unbroken. Blisters are a unique surface defect because they form between the coating and substrate and will guarantee no adhesion due to enclosures at the part surface.

Grinning Defect in Paint

The failure of a paint system to hide or obliterate the colour of the original surface or the previous paint. It may be caused by applying too few coats, using an undercoat of unsuitable colour, excessive spreading or uneven application of the paint.

Sagging Paint Defect

Runs, sags and curtains are the downwards movement of paint that can appear shortly after the application and before the setting of the paint. Sagging is usually apparent on local areas of a vertical or curved surface. When sagging occurs over a long distance this is described as a curtain.

Spray Paint Defects

Here are some of the most common faults and misconceptions of spray painting.

- Time.

- Dimpling.

- Cracking/Webbing.

- Sanding between Paint Coats.

- Paint Quality.

- Grainy paint finish and Paint runs.

- Orange Peel.

- Misting/Fogging.

Types of Paint Defects on Cars

- Swirl Marks or Spider Web Swirls.

- Marring.

- Micro Marring.

- Buffer Trails and Holograms.

- RIDS (Random Isolated Deep Scratches)

- Bird Droppings a.k.a. “Bird Bombs”

- Bird Drop Etchings.

- Light Water Spots.

Car Paint Defect Types

Here you will find the most common paint defects:

- Advice on paint defects.

- Aftercare of vehicle paintwork.

- Bleeding.

- Blistering.

- Chalking.

- Clouding.

- Corrosion creepback.

- Cracking.

What Is the Most Common Congenital Heart Disease?

The most common type of heart defect is a ventricular septal defect (VSD).

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Stone | Classification of Stones | Application of Stone | Advantages of Stone | Disadvantages of Stone

- What Is Frost Wall | Types of Frost Wall | Requirements for Frost Wall Construction | Application of Frost Wall | Advantages of Frost Wall | Uses of Frost Wall

- What Is Plate Load Test | Method of Plate Load Test | Limitations of Plate Load Test | Advantages & Disadvantages of Plate Load Test

- What Is Isolated Foundation | Types of Isolated Foundations | Shape of Isolated Foundations | Design of Isolated Foundation | Advantage & Disadvantage of Isolated Foundation

- What Is Tunel | Types of Tunnels | What Are Tunnels Used for | Classification of Tunnel | How Are Tunnels Built |Advantages & Disadvantages of Tunnels

[/su_note]

Originally posted 2022-11-04 06:46:52.