What is FerroCement| Properties| Materials required| Uses| Advantages| Disadvantages

Table of Contents

What is Ferrocement?

Ferrocement is a substance of wire meshes & cement mortar. It was 1st developed by P.L.Nervi, an Italian architect in 1940. This material has obtained widespread application in construction during the last 20 years.

Ferrocement is a versatile sort of composite substance manufactured from OPC (Ordinary Portland Cement) & layers of steel wire mesh & bijou diameter steel bars tightly bound altogether to generate a stiff structural form.

It is additionally termed as ‘ferro concrete’ or ‘reinforced concrete. Wire mesh is employed as an essential reinforcement material. The wire mesh passes on tensile strength & ductility to the substance while the mortar generates the brawn against cracking.

Properties of Ferrocement

It’s a kind of sleek reinforced concrete construction, during which huge quantity of continuous bijou diameter wire meshes homogeneously throughout the cross section. Mesh are manufactured of metal or identical material.

Instead of concrete Portland cement mortar is employed. Strength depends on two factors, viz., quality of sand/cement mortar mix & quantity of reinforcing materials used. It is basically a versatile kind of reinforced concrete & possesses high stiffness & tensile brawn.

It ameliorates the punching shear resistance & influence. It is light- weight & undergoes massive deformation earlier. It is inexpensive & significantly durable. A low w/c ratio generates the non-penetrable structures.

Materials Required for Making Ferrocement

- Cement

- Fine Aggregate

- Water

- Admixture

- Mortar Mix

- Reinforcing mesh

- Skeletal Steel

- Coating

1. Cement Mortar Mix

Generally, the principal constituents of ferrocement are Ordinary Portland Cement (OPC) & Fine Aggregate Matrix In ferrocement, fine sand ought not to be utilized. To boost the workability, stability & brawn & likewise to diminish permeability, plasticizers & admixtures are added to ameliorate the balance.

The particle size of sand ought not to be greater than 2.36 millimeters (can make the mortar porous) & less than 1.18 millimeters (requires excess water to the non-penetrable structure). Fine Aggregate (Sand) occupies 60- 75% mortar volume

The matrix makes up 95% of the composite & it’s characteristics depends on it.

2. Blend Proportions

Sand: Cement ratio = 1.5:2.5 (by mass)

Water: Cement ratio = 0.35:0.60 (by mass)

3. Reinforcement

In ferrocement, 2 kinds of reinforcements are:-

- Skeleton Steel

- Steel Wire Mesh

3.1 Skeleton Steel

Skeleton steel possesses large-diameter (about 3 to 8 millimeters) bars ranging from 75mm to 100mm & it is supplied as welded wire fabric or tied-reinforcement. It’s primary function is to carry the wire mesh within the shape of the structure.

Places where higher stresses may occur, mild steel bars are utilized. Employed to impart structural brawn in boats, barges etc Reinforcement ought to be dust-free, rust-free & free from other impurities

3.2 Steel Wire Mesh

In wire mesh, 6-20 millimeters center to center gapping is supplied & it is usually manufactured from galvanized wire (0.5-1.5 millimeters diameter). The wire mesh is available as welded wire mesh or square woven wire mesh or mesh of expanded metal etc.

The yield strength of plain wires utilized in fabric ought not be over 415 MPa & 500 MPa for deformed wires. The metal content may range between 300-500 kg / m3 of mortar. Welded wire mesh has hexagonal or rectangular apertures

Expanded metal lath is additionally used

4. Construction Process

The construction process of ferrocement is split into the subsequent 4 phases as given below:-

- Fabricating the skeletal framing system.

- Applying rods and meshes.

- Plastering.

- Curing.

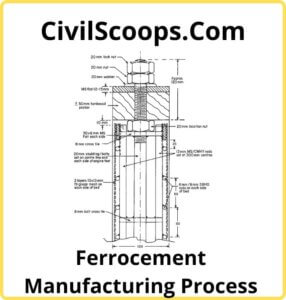

5. Ferrocement Manufacturing Process

5.1. Hand Plastering

In this method, control thickness is strenuous & least thickness is a stream that is 2cms.

5.2. Semi Mechanized Process

This system additionally is referred to as semi-mechanized since the mould may be rolled to aid the dynamic to mortars.

5.3. Geniting

The gun-running processes are often adapted to utilize the mortar to the wire mesh system.

5.4. By Centrifuging

Centrifuging courses are adopted for the development of rigid cylindrical units.

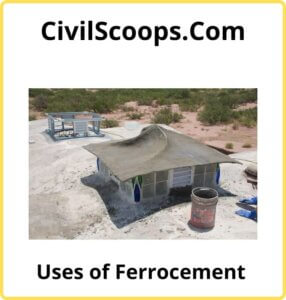

5.5. Uses of Ferrocements in Construction

- Housing.

- Marine.

- Agricultural.

- Rural Energy.

- Anticorrosive Membrane Treatment.

- Miscellaneous.

- Boats, fishing vessels, barges, cargo tugs, catamarans, yachts & flotation buoys.

Uses of Ferrocement

- Marine Uses: Ferrocement is employed for developing boats, finishing vessels, barrages, cargoes, tugs, docks, floating buoys & water or fuel tanks.

- Water Supply & Sanitation Uses: It is employed for Water tanks, sedimentation tanks, well casings, septic tanks & swimming pools linings. g. Hirakud dam

- Agricultural Uses: Again, it is utilized for grain Storage bins, silos, water tanks, pipes, canal linings for underground pits, shells & poultry farms & irrigation channels.

- Housing Uses: Further, it is utilized for Mosque domes, shelters, sheds, domed structures, precast housing elements, wall panels, sandwich panels, hollow core slabs, permanent from work & corrugated roofing sheets water cisterns & repair and renovation of existing houses, community centers, wall panels, etc.

- Rural Energy Uses: It is again employed for Biogas digesters, biogas holders, incinerators & panels for solar power collectors.

- Permanents Framework Uses: Also utilized for Reinforced or prestressed concrete & for columns, beams, slabs, etc.

- Miscellaneous Uses: Moreover, it is also utilized for Mobile homes, kiosks, wind tunnels, silos & cans.

- Modern Uses: Here, the modern use of ferrocement are as follows.

- Residential & Public Buildings.

- Industrial Structures.

- Agricultural structures.

- Transportation Structures.

Advantages & Disadvantages of Ferrocement

Advantages of Ferrocement

Here, the pros of ferrocement are as follows.

- Raw materials are effortlessly obtainable in most countries.

- Can be fabricated into any specific shape & thickness.

- Minimum labour skill required.

- Effortless construction, light-weight & lengthy lifetime with fine durability.

- Least material cost & affordable maintenance cost.

- Better resistance against earthquake, fire & corrosion.

- It can be moldable & of one-piece construction.

- They possesses loftier tensile strength i.e. high ductility & are resistant to crack.

- It is ideal for special structures like shells & roofs, water tanks, etc because it can be fabricated in any desired shape.

- For precast merchandise, it’s an ideal substance.

- It’s an ideal material for precast merchandise.

- They are environmentally friendly.

- Possesses ability to undergo huge deflection

- Improved impact resistance & sturdiness

- Good impermeability

- Low strength to weight ratio

- Capital & native convention of construction procedure.

- Doesn’t need ponderous plant or machinery.

Disadvantages of Ferrocement

Here, the cons of ferrocement are as follows.

- Structures generated from it can be punctured by hitting with pointed objects or forceful collision i.e. vulnerable to sharp objects & has low shear strength.

- Corrosion of reinforcing materials occurs due to the unfinished coverage of metal by mortar.

- It is strenuous to fasten to Ferrocement with bolts, screws, welding & nails etc.

- Huge no of labors required & hence expensive.

- Cost of semi-skilled & unskilled labors are lofty.

- Tying & fastening of rods & mesh is tedious & time consuming.

- It can impair in tyrannical environments. In seawater, reinforcing materials may get corroded, if the thickness of the canopy isn’t sufficient.

- The special core is essential to make sure that steel cover reinforcement is sufficient.

- Rust can pop up on reinforcement if not canopied sufficiently by mortar.

- It is strenuous to perform welding etc properly.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””].

Ferro Cement

Ferrocement or ferro-cement is a system of construction using reinforced mortar or plaster (lime or cement, sand, and water) applied over an “armature” of metal mesh, woven, expanded metal, or metal-fibers, and closely spaced thin steel rods such as rebar.

Ferrocement Water Tank

Ferro-cement structures are created by constructing a frame from thin steel rods (rebar) that is then covered with a metal mesh to create the form of the structure. Then thin layers of sand and cement are plastered over, resulting in a hard, strong finish, ideal for a water tank

Amerimix Pre Blended Mortar Type S

Type s is the common choice for many below-grade applications, such as masonry foundations, manholes, retaining walls, and sewers, as well as at-grade projects like brick patios and walkways.

Amerimix Mortar Type S

Type s mortar mix is a preblended mixture of sand and masonry cement or sand, lime and portland cement. For laying brick, block and stone in load bearing walls and below grade applications.

Cement Repair Mix

But what you can also do is get a container like that which is an old protein container put the cement in there and just simply give it a really good shake rolling around on the floor.

Mortar Mix near Me

Thinset mortar is again a combination of portland cement and a fine sand mixture, however, the mix ratio of sand to cement is different. With thinset mortar the ratio of cement and sand is one to one. Thus it is a stickier mixture that produces better adhesion.

Quikrete Mortar for Shower Pan

The quikrete floor mud is a concrete mix manufactured by quikrete which is ready for use in creating shower pans, slate, travertine, and marble floor tiles. When mixed with water, it creates a smooth and water-resistant surface which is ideal for shower pans.

Quikrete Roof Tile Mortar

Quikrete roof tile mortar fl-15 is designed for installing flat, low, and high-profile clay and concrete tile on roofs over granular roofing paper or other approved underlayment materials. It is approved for use in the hvhz (high velocity hurricane zone).

Fast Set Mortar Repair

Fastset™ repair mortar should be trowel applied to the damp surface. Apply a thin layer with heavy trowel pressure, and then go back and build up to the desired thickness. Fastset™ repair mortar obtains high bond strength without the use of bonding adhesives or acrylic additives.

Waterproof Mortar Mix

While for the same job, but with much softer limestone, a completely different mixing ratio is advised, namely 1 part cement, 9 parts sand, 2 parts lime. The correct ratio for cement mortar must therefore be determined on the basis of the type of brick and the location of the building (inside or outside).

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Hand Level Surveying | What Is Site Level? | What Is Hand Level? | How to Use a Hand Sight Level | Estimating Distances with a Sight Level

- Types of Cement Grades | Difference Between 33, 43 &53 Grade Cement

- What Is Panelled Window? | What Is Glazed Window? | Difference Between Paneled Window and Glazed Window

- What Is Estimate? | Types of Estimate | Advantage of Estimate | Disadvantage of Estimate

- What Is Epoxy? | What Is Epoxy Flooring? | Types of Epoxy Flooring | Advantages of Epoxy Flooring | Disadvantages of Epoxy Flooring | Uses of Epoxy Flooring | Application Process of Epoxy Flooring

- Difference Between Short Column and Long Column

[/su_note]

Originally posted 2024-04-05 05:13:58.