What Is Concrete Forms | Types of Concrete Forms, Uses, Advantage, Disadvantages and Applications

Table of Contents

What Is Concrete Form?

A concrete form is a system of formwork for reinforced cement concrete which is made with rigid thermal insulation.

The concrete formwork is necessary to provide a shape of that concrete.

Types of Concrete Forms, Uses, Advantage, Disadvantages and Thai applications

Types of Concrete Forms

For the concrete casting there are many types of concrete forms are used, that’s are below-

1. Wooden Form

The wooden form is the most conventional and basic type of concrete form, for casting concrete it is mainly used.

The height of the wooden forms should not be exceeding 6 inches.

The wooden form consists of some wooden boards that are tight between either screwed or nailed to get a desired formwork or mold shape.

For the correct level or slope special leveling equipment are used as per requirements.

When we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

Before pouring the concrete, we ensure that the inside surface of the concrete form should be applied with any form of releasing agent or low-grade oil, so that the concrete does not attach to the boards.

If we properly maintained and cleaned the boards, then it can be used much time for work.

Uses of Wooden Concrete Form

The uses of wooden form are below-

- The uses of wooden form is, when we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

- The wooden form is the most conventional and basic type of concrete form, for casting concrete it is mainly used.

Advantage of Wooden Concrete Forms

Advantages of wooden concrete forms are below-

- The advantage of wooden concrete forms is, to make any shape of the residential building the wooden concrete forms are used.

- Another advantage of wooden concrete forms is, the wooden form is the most conventional and basic type of concrete form, for casting concrete.

Disadvantage of Wooden Concrete Forms

Disadvantages of wooden concrete forms are below

- The disadvantage of the wooden concrete form is, for the heavy concrete structure, the wooden concrete forms cannot be used.

- A wooden concrete form is most costly.

Application of Wooden Concrete Forms

The applications of wooden form are below-

- The wooden forms can be applied, when we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

- It may be applying for any residential building construction and industrial construction.

Also Read: Why Hairline Cracks in Concrete | Types of Cracks in Concrete

Useful Article for You

- What Is a Contour Interval

- What Is a Door Frame

- What Is Rafters

- What Is a Spandrel Beam

- What Is a Pony Wall

- What Is the Density of Sand

- What Is Modulus of Rupture

- What Is a Conceptual Drawing

- What Is a Slab in Construction

- What Is Skirting

- What Is Falsework in Construction

- What Is Mezzanine Level

- What Is Mortar Made Of

- What Is Plywood

- What Is Undercoat

- What Is Cbr

- What Is a Benchmark in Surveying

- What Is Pier and Beam Foundation

- What Is Workability

- What Is a Flyover Bridge

- What Is the Standard Door Frame Size

- What Is Kerbs

- What Is a Fire Escape

- What Is Lumber Used For

- What Is a Weep Hole

- What Is Tie Beam

- What Is Typical Counter Height

- What Is Flag Stone

- What Is a Tremie

- What Is a Lean-To on a House

- What Is Dpc in Construction

- What Is Varnish?

2. Insulated Concrete Form

Insulated concrete form manufactured as a hollow block and used as an insulating material used for constructing building blocks.

On the foundation slab these techniques are constructed and the reinforcement is placed inside these blocks and filled with the required cast or slump concrete.

To get the excessive energy efficiency, the concrete and forms are laid like sandwiches.

By pouring with the concrete in the boards, it is not necessary to remove the board at first as possible.

Uses of Insulated Concrete Forms

- The insulated concrete forms use as insulating materials used for constructing building blocks.

- To get the excessive energy efficiency, the concrete and forms are used like sandwiches.

- The insulated concrete forms can be used as a building designer material.

Advantage of Insulated Concrete Forms

- It can be used for construct building blocks.

- By this we can obtain desired design on the residential building.

Disadvantage of Insulated Concrete Forms

The disadvantage of insulated concrete forms is below

- The disadvantage of insulated concrete forms is, because of it is a hollow block, for this the strength of this concrete blocks is less from the other concrete forms.

- For installation of this types of forms expert workers are needed.

Applications of Insulated Concrete Forms

- The insulated concrete forms can be applied, to make a building block.

- And it also can be applying, for the design of building walls and floors.

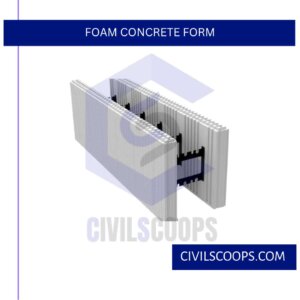

3. Foam Concrete Form

The foam concrete form follows non-traditional methods so the specified finish is obtained that the concrete is poured upside down.

This types of forms are manufactured from acrylic glass, melamine, or laminated boards.

By that foam concrete forms, we obtained a creative look, create adverse spaces to the ultimate concrete cast.

Uses of Foam Concrete Form

- The foam concrete form can be used for; the specified finish is obtained and the concrete is poured upside down.

- Another uses of this is, by that foam concrete forms, we obtained creative look, create adverse spaces to the ultimate concrete cast.

Advantage of Foam Concrete Form

The advantages are below of foam concrete form-

- The advantage of foam concrete form is, by this we can obtain a creative look, create adverse spaces to the ultimate concrete cast.

- By this we can decorate the building as our requirement.

Disadvantage of Foam Concrete Form

Some disadvantage of foam concrete form is given below-

- The uses of foam concrete form are costlier in the construction and needed more time for the construction. This is a common disadvantage of this.

- For this expert’s workers are needed.

Applications of Foam Concrete Form

The applications of foam concrete form are given below-

- The applications of foam concrete form are, we obtained creative look, create adverse spaces to the ultimate concrete cast.

- We can be applying for; the specified finish is obtained and the concrete is poured upside down.

Also Read: What Is Building | Types of Building

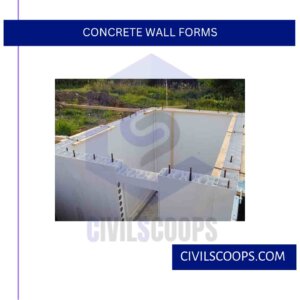

4. Concrete Wall Forms

The concrete wall forms techniques we used to make of large space walls, piers, and foundations.

The concrete wall forms are some pre-fabricated formation techniques.

The concrete wall forms techniques are generally made with steel framing from either engineering wooden or solely steel and individual elements are joined together by latches or pins.

In this technique to carry the reinforcement ties are used. When the wall forms are available in numerous shapes and sizes.

For the custom shape, there are have additional producers that’s should be followed as a requirement.

Uses of Concrete Wall Forms

The uses of concrete wall forms are given below-

- The concrete wall forms techniques we used to make of large space walls, piers, and foundations.

- When the wall forms are available in numerous shapes and sizes, in this technique to carry the reinforcement ties is used.

Advantages of Concrete Wall Forms

There have been many advantages of concrete wall forms that are below-

- The common advantage of concrete wall forms is, it can be used to make of large space walls, piers, and foundations.

- Another advantage of concrete wall form is; it can be easily usable.

Disadvantages of Concrete Wall Forms

There have been many disadvantages of concrete wall forms that are below-

- The disadvantage of concrete wall forms is, it is not used for small works like small residential building, etc.

- Another disadvantage of concrete wall forms are its increase the construction cost of the structure.

Applications of Concrete Wall Forms Is

There have been many applications of concrete wall forms that are below-

- We can apply the concrete wall forms, to make large space walls, piers, and foundations.

- For decorating desired shape and size of the structure of a building, we can be applying the concrete wall forms.

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Linear Distance

- What Is Development Length

- What Is Cement Plaster

- What Is the Difference Between Mortar and Concrete

- What Is Shovel

- What Is Lintel in Construction

- What Is Tar

- What Is Rebar Used For

- What Is Piers

- What Is Ferrocement

- What Is the Difference Between a Basement and a Cellar

- What Is a Monolithic Slab Foundation

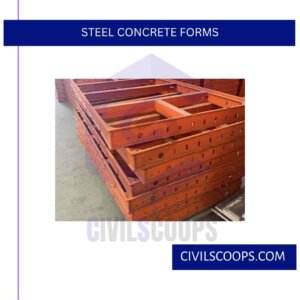

5. Steel Concrete Forms

The steel concrete forms are generally manufactured by steel, even 2000 work cycles the stability of steel forms may be achieved, if properly the form used and maintained.

From the wooden concrete forms, it is most durable and more costly.

For decreasing the errors in the concrete forms, steel-concrete forms are used, because of the steel forms do not absorb moisture from the concrete.

Uses of Steel-Concrete Forms

This form opts-in large-area walls, foundations, piers, etc.

This is generally made with engineering wood with steel framing.

Advantages of Steel-Concrete Forms

The main advantage of steel concrete form is its robust, sturdy, and longer lifespan.

Assembled and removing process is very fast compared to others.

Disadvantages of Steel-Concrete Forms

It is not economical because the cost is higher.

The weight of these are too much so it requires lifting equipment.

Corrosion will easily occur in this.

Shape and size are limited in this.

Application of Steel-Concrete Forms

This is generally made with engineering wood with steel framing.

This form opts in large-area walls, foundations, piers, etc.

Also Read: Load-Bearing Vs Partition Walls | What Are Walls | Classified of Walls

Free Form Concrete

Here are some details about free form concrete:

- Off-form concrete is a construction material that’s created by pumping concrete through a nozzle to form it into a predetermined shape

- Sprayed concrete is an ideal material for constructing freeform structures because it can form curved shapes

- Wood has been the concrete contractor’s formwork of choice for years because it’s relatively inexpensive, lightweight, and easy to understand and replace

- Plastic concrete forms can be used to create slants or curves, and can work around landscaping obstructions

Concrete forms are solid barriers that help to hold the fluid concrete in place until it hardens and acquires a particular shape.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Concrete Form?

Formwork, also known as concrete forms, is a temporary or permanent mould used to create concrete slabs and structures. It’s a barrier that holds the fresh concrete in place and helps with shaping the concrete until the concrete is strong enough to hold its own weight and shape.

What to Use for Concrete Forms?

Wood is the most cost-effective and popular material for concrete forms. Properly built wooden forms are lightweight, flexible and durable. When choosing the wood for concrete forms, select straight, flat lumber with minimal knots.

What Is Insulated Concrete Forms?

Insulating concrete form or insulated concrete form is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs.

What to Spray on Concrete Forms?

KLEEN KOTE 111 is a long-lasting, biodegradable form release agent and equipment protectant formulated with corrosion-inhibiting properties. KLEEN KOTE creates a virtually non-stick coating on the surface of tools, machinery, vehicles and concrete form work when applied.

What to Use for Flexible Concrete Form?

Masonite siding has often been an option for forming curves — it’s stiff, yet bendable. Some contractors use landscape edging material made out of metal. Others cut “kerfs” (grooves) into two-by-fours to allow the wood to bend, or they rip thinner plywood to the heights that they want their forms to be.

What Are Concrete Forms Made Of?

Concrete forms are most often made of wood. Metal forms are also an option. Other materials available for concrete forms include plastic, resin, and fiberglass. These materials do not have the proven track record of wood and metal.

Types of Concrete Forms

- Wood Forms. Using wood to form concrete is the oldest, most common method.

- Adjustable Column Forms. Adjustable all-steel columns forms can be designed for projects requiring up to 48” square columns.

- Handset Forms. Handset Systems are some of the easiest formwork systems to assemble and use.

Types of Concrete Formwork

The main types of formwork systems in use now are:

- System column formwork.

- Horizontal panel.

- Slipform.

- Jumpform.

- Vertical panel systems.

- Permanent formwork used in some types of hybrid concrete construction.

Round Concrete Column Forms

Round Column Features

Forms are designed for long life, dependable service, and for producing the lowest total in-place concrete costs. EFCO Round Column forms are available in 12″ to 144″ diameters. Forms 48″ and smaller are supplied in 180° segments. Forms 54″ to 96″ are available in 90° segments.

Cast in Place Concrete Countertop Edge Forms

Forms that are designed to attach directly to your cabinet base, fill with concrete, and then simply snap off the front of the plastic form for a finished concrete countertop edge.

Eps Concrete Forms

EPS is used to create molds to form concrete shapes such as columns, counter tops and sinks. It can be used to form parapet caps and other shapes that require greater detail then can easily or economically be produced with other materials.

Concrete Forming Companies

Concrete forming creates frameworks to give structure to concrete as it cures. Forms are used to create patios, retaining walls, driveways, countertops, foundations, and more. Forming costs range from around $0.30–$2 per sq. ft.

Fast Form Concrete

Made of high density polyethylene fabric, Fastfoot® is a green replacement of lumber and plywood for forming concrete footings. A 100′ roll of Fastfoot® forms the same concrete as 1,500 pounds of lumber.

Icf Block House

ICF stands for Insulated Concrete Forms. Insulated Concrete Forms (ICF) are hollow foam blocks that are stacked into the shape of the exterior walls of a building, reinforced with steel rebar, and then filled with concrete.

Fast Tube Concrete Form

Fast-Tube™ is a utility fabric column form for forming round concrete columns.

Icf Foundation Waterproofing

Waterproofing ICFs

Waterproofing is a multi-step project, involving many areas of the ICF wall and other building components. Moisture control begins with flashing at the roof line, parging at grade level, membranes below grade, air gap barriers, and foundation and site drainage to route water away from the structure.

Patch Holes in Concrete Wall

Large Holes

Apply cement adhesive to the new concrete and use ready mix concrete to fill the patch on the wall. You should cover the hole with a piece of plywood temporarily. Use water several times to avoid uneven drying. This is the process of patching cracks in concrete walls.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is a Cavity Wall

- Repairing a Burst Pipe

- All About No Hot Water in The House

- New Civil Engineering Technology 2023

- Understanding Oblique Drawing: Techniques, Examples, and Applications

[/su_note]

Originally posted 2023-09-28 12:41:35.