Difference Between Lap Length and Development Length

Table of Contents

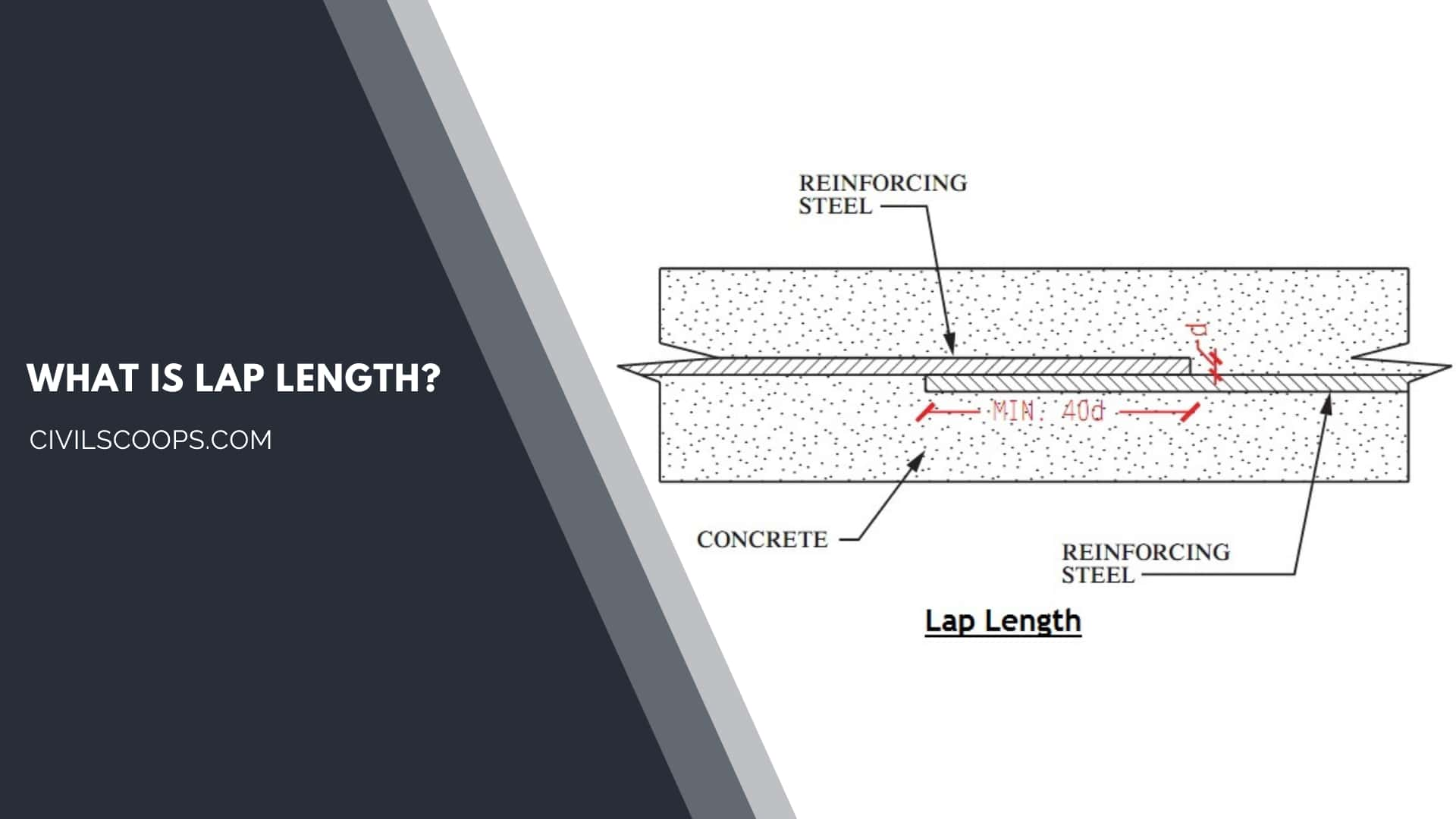

What is Lap Length?

Lap Length is required when bars placed short of their required length (due to nonavailability of longer bars) need to be extended.

- Lap Length is also required when the bar diameter has to be changed along the length (as is sometimes done in columns).Branding

The purpose of ‘Lap’ is to transfer the axial force effectively from the terminating bar into the connecting bar with this same line of action in the junction.

This invariably introduces stress concentrations at this surrounding concrete. These effects should be minimized by

- Using proper splicing techniques.

- Keeping these lapping locations away from sections with high flexural/shear stresses. and

- Staggering the locations of splicing at the individual bars of a group (as typically in a column).

When splicing in such situations becomes unavoidable, special precautions need to be employed, such as

- Increasing the length of the lap length (In lap splices and lap welding)

- Using spirals or closely-spaced stirrups around the length of the stirrups.

Type of Lapping Method:

- The lapping of bars (lap splice)

- Welding of bars (welded splice)

- Mechanical connection.

Also Read: What Is Rebar | Why use Reinforcement in Concrete | Types of Steel Reinforcement Bars

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is an Undercoat

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is the Standard Door Frame Size

- What Is a Spandrel Beam

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Pony Wall

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is a Slab in Construction

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Plum Concrete

- What Is Shell Structure.

- What Is Lumber

- What Is the Strongest Foundation for a House

- What Is the Meaning of Soundness of Cement

- What Is Flyover Bridge

- What Is Under Reamed Pile

- What Is Weir

- What Is Inverted Beam

- What Are the Advantages of Levelling?

- What Is Sunk Slab

- What Is Brick Bat Coba

- What Is Isolated Footing

- What Is Long Column

- What Is Plate Load Test

- What Is Formwork

- What Is Concealed Beam

- What Is Acp

- What Is Wbm Road

- What Is Slab

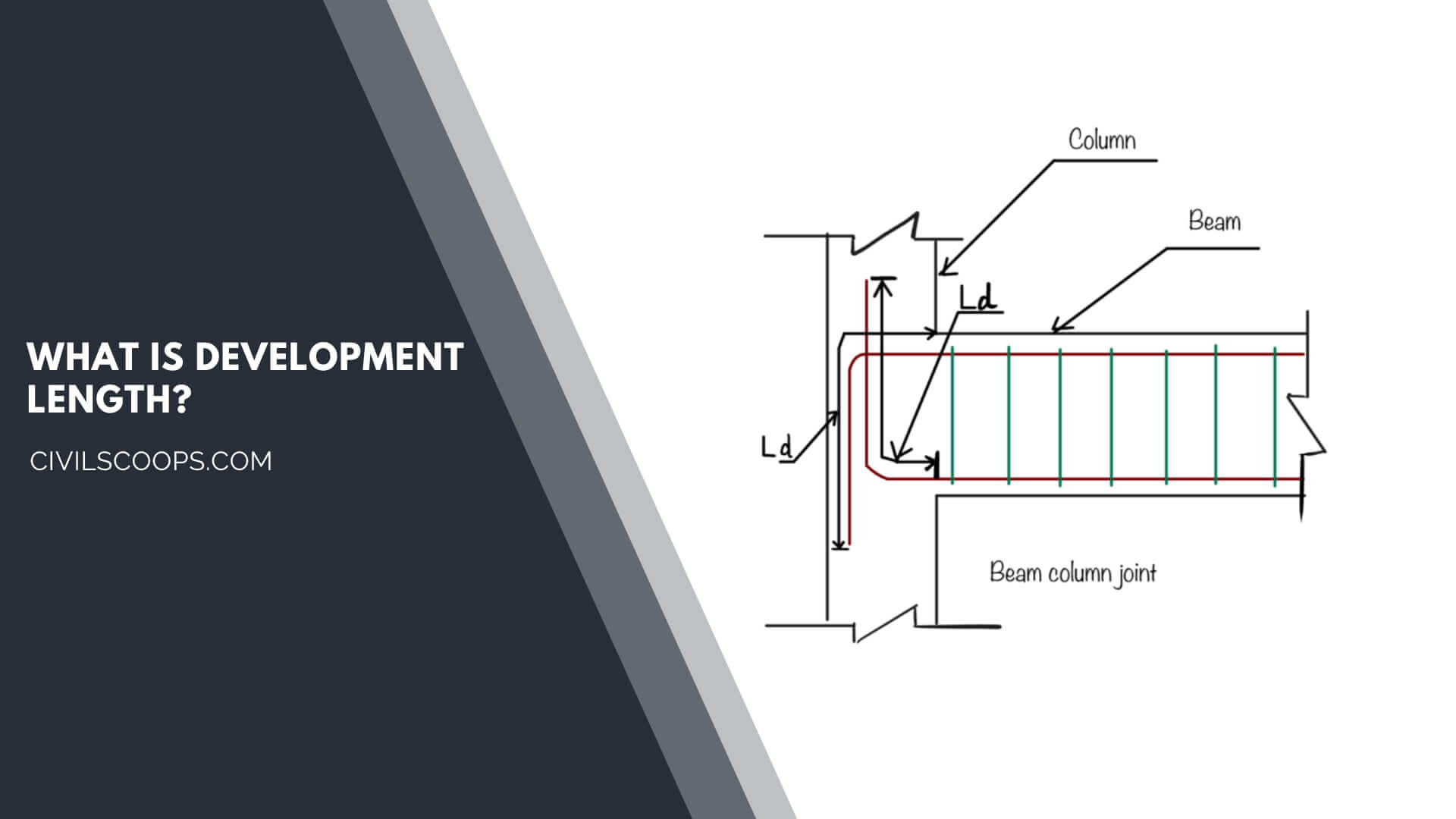

What is Development Length?

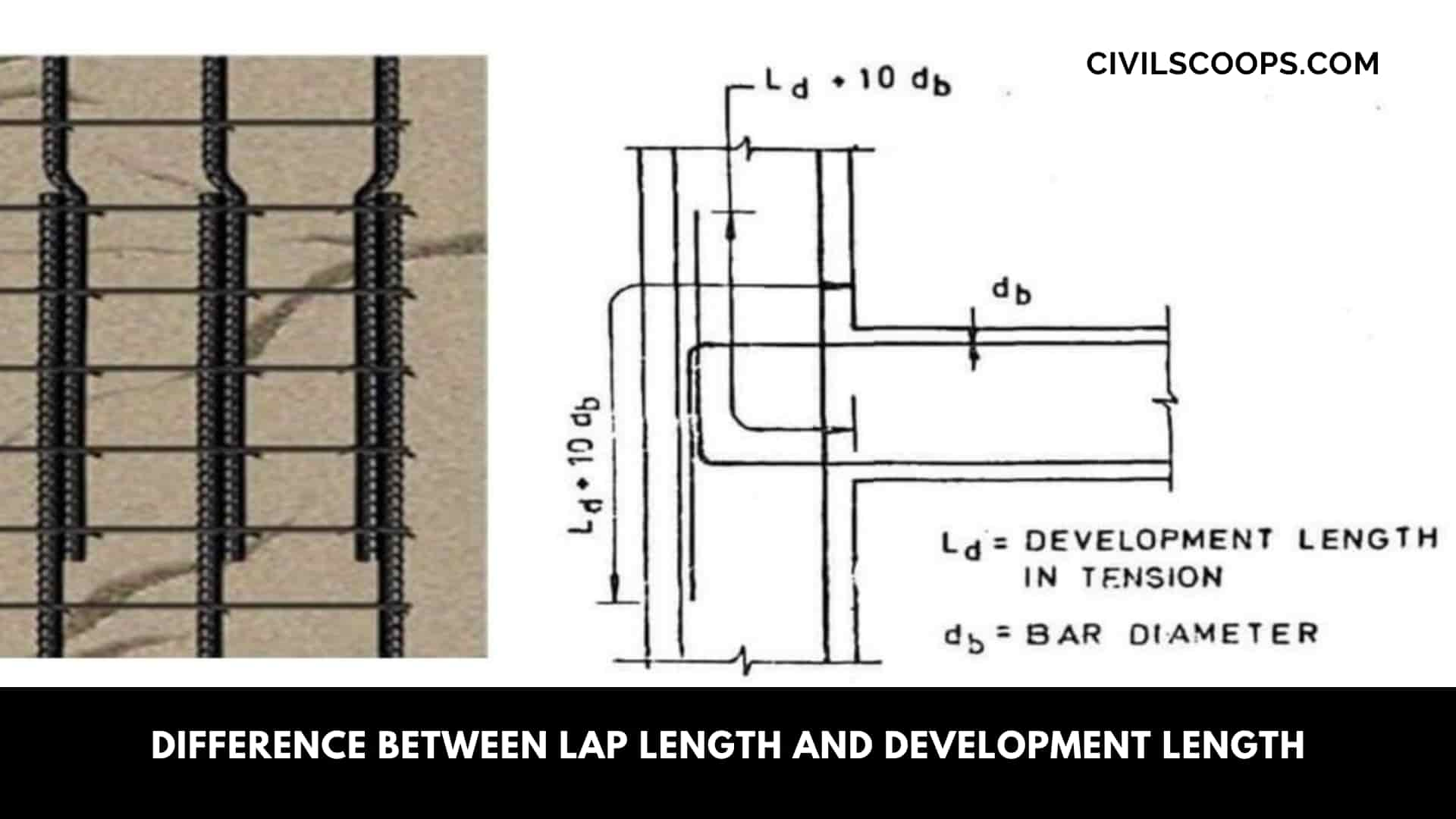

The development length is defined as the length of the bar required on either side of the section under consideration. To develop the required stress in steel at that section through a bond.

The calculated tension or compression in any bar at any section shall be developed on the peach side -of the section by an appropriate development length or end anchorage or by a combination thereof. as per IS code 456-2000, Page-42, Cl. 26.2

The preceding discussion suggests this concept of development length of a reinforcing bar.

The development length is defined as the length of embedment necessary into developing the full tensile strength of this bar, controlled by either pullout or splitting.

With reference to as per below fig, the moment, and therefore the steel stress, is evidently maximum in point a (neglecting the weight of the beam) and zero at the supports.

If the bar stress is f, at a, then the total tension force Abl, must be transferred from the bar to this concrete in the distance 1 by bond forces.

To fully develop this strength of the bar, the distance one must be at least equal to the development length of this bar, established by tests.

In the beam of as per above fig, if the actual length /is equal to or greater than the development length Id, no premature bond failure will occur.

The beam will fail at bending or shear rather than by bond failure. This will be so even when, in the vicinity of cracks, local slip may have occurred over small regions along this beam.

It is seen that the main requirement for safety against bond failure is this: the length of the bar, from any point of given steel stress (L or at most f) to it’s nearby free end, must be at least equal to its development length.

If this requirement is satisfied, this magnitude of the nominal flexural bond force along the beam, as given by Eq. (as below), is of only secondary importance, since the integrity of this member is ensured even in the face of possible minor local bond failures.

U = V/JD

However, if this actual available length is inadequate for full development, special anchorage, such as by hooks, must be provided.

Also Read: Concrete Material Calculation / Concrete Quantity

Difference Between Lap Length and Development Length

[su_table responsive=”yes” alternate=”no”]

| SR.NO. | DEVELOPMENT LENGTH | LAP LENGTH |

| 1 | Length of reinforcement bar required to transfer load or stress developed in a reinforcement bar into the concrete. |

Length of reinforcement bar required to completely transfer load or stress from one bar to another bar

|

| 2 | It is denoted by Ld |

It minuteness the continuity in the structure

|

| 3 | It is always provided at the end of beam, column, or slab |

It is provided when the length of bars ends.

|

| 4 | It is also useful for providing grip & support & doesn’t allow slipping |

It is transferred to continuity and also transfers stees from one bar to another bar.

|

| 5 | This is bound between concrete and reinforcement. |

This is a bond between reinforcement and reinforcement.

|

[/su_table]

Also Read: Reinforced Concrete Frame | Concrete Frame Construction Details | Concrete Building Construction

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Difference Between Lap Length and Development Length

- Lap Length: The length where reinforcing bars overlap to ensure continuity and strength in concrete structures.

- Development Length: The length of reinforcement needed to be embedded in concrete to effectively transfer loads between the steel and concrete and achieve full strength.

What Is Lap Length?

This amount of overlapping between two bars is called “lap length”. Lapping is usually done where minimum bending stress is encountered. In general, lap length is 50d which means 50 times the bar diameter, if both bars are of same diameter.

What Is Development Length?

The term “development length” signifies the bar length that must be present for the stress to be transferred successfully into the concrete. For concrete and steel, it is the length of the bar that must be implanted into the material to generate enough tension to provide the appropriate bond strength.

Lap Length Formula

Lapping is usually done where minimum bending stress is encountered. In general, lap length is 50d which means 50 times the bar diameter, if both bars are of same diameter.

Lapping Length

The lapping length refers to the length of overlap required for two reinforcing bars (rebars) to ensure continuity of stress transfer from one bar to another in reinforced concrete structures. When constructing concrete elements like beams, columns, or slabs, reinforcing bars are embedded to provide tensile strength to the concrete.

What Is the Minimum Lap for Rebar?

As per IS 456, the straight length of the lap should not be less than 15ϕ or 200 mm (whichever is more). The lap length must be at least equal to the development length. In no case, the lap length should be less than 30ϕ for flexural and direct tension and 24ϕ for compression.

What Is the Development Length of Steel Reinforcement?

Development length is the amount of reinforcement embedded in a column to achieve the suitable bond strength between the steel and concrete. It has a crucial role to play in the stability of a structure as it helps to prevent joint slippage.

Minimum Lap Length for Reinforcement

As a general guideline, minimum lap lengths for reinforcement bars are typically specified in the range of 40 to 60 times the diameter of the bars being spliced or overlapped. However, it’s crucial to consult and adhere to the requirements outlined in the applicable design codes or standards, as they may vary depending on the structural requirements and regional specifications.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Properties of Sand

- Basic Plumbing System

- Rotten Egg Smell In Car

- Types of Concrete Blocks

- Construction Risk Management

[/su_note]

Originally posted 2023-11-22 10:39:46.