What Is Pointing | 7 Types of Pointing | Keyed Pointing

Table of Contents

What Is Pointing?

Pointing is the term given to the “finish” that sits between the bricks or stone used to build your home. This process is crucial in pointing in construction.

Depending on the age of the building, the mortar used to deposit the stone or brick will be made of lime or, more recently, cement.

What is pointing? Pointing incorrectly causes irreparable damage to older buildings. It is essential to understand what mortar joints really do for the fabric of the home.

The function of mortar on the wall is to act as a foundation between stones and varies from fine joints in the stonework to larger joints in rubble masonry walls.

The joints are effectively reduced in size by inserting small stones and ‘cut’ pieces of stone. While acting as a bed, the mortar must also perform other functions:

In the context of pointing in civil engineering, it must prevent water from penetrating through the joints due to its physical presence almost like a masonry ‘sponge’ but it must allow the wall to breathe and drain, porosity being a key factor when choosing a mortar to refer to.

It must be flexible to allow movement/settlement of the structure due to thermal responses and settlement within the structure. Many former large buildings are not designed with today’s modern expansion/contraction joints.

The strength of the mortar should always be less than that of the surrounding stones and should be considered as a sacrificial element of the wall and seen as a maintenance item that needs to be replaced, possibly every century.

The condition of the stone walls cannot be seen in isolation, and replacing any walls will not cure water ingress problems caused by other construction failures, such as gutters, roofs, and lead. They must be in good condition to maintain the useful life of the wall elements.

The walls need to breathe – and, if the indicator does not allow it, the wall will quickly deteriorate. Mortar joints are the lungs of a wall – they allow water inside the structure to enter and exit freely.

If the water tries to come out through stone or brick, it will slowly disintegrate. Block the mortar joints, and the wall will be destroyed.

The mortar must be softer than the material with which the wall is constructed. The indication must be subservient to the material with which the wall is constructed and visually assume a secondary function.

Types of Pointing In Brick Construction

Pointing is the finishing of mortar joints in the construction of bricks, often referred to as pointing work. Aiming is the implementation of joints at a depth of 10 mm to 20 mm and fills it with better quality mortar in the desired shape.

It is made for cement-pointing mortar and lime mortar joints. Exposed joints are considered the weakest and most vulnerable points from which rainwater or moisture can enter.

Also Read: What Is Classification of Bricks | Classification of Bricks Different Base

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is an Undercoat

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is the Standard Door Frame Size

- What Is a Spandrel Beam

- What Is a Fire Escape

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Pony Wall

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is Rafters

- What Is a Slab in Construction

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Inverted Beam

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Short Column

Mortar for Pointing Works

- 1: 2 lime mortar (1 fat lime: 2 sand)

- 1: 3 cement mortar (1 cement: 3 sand)

Surface Preparation for Aiming

All masonry joints are joined to a depth of 20 mm, while the mortar is still soft. The joints and surfaces are cleaned and then completely wet.

Pointing Methods

After preparing the surface, as mentioned above, the mortar is carefully placed on the joints using a small spatula. The mortar placed must have the desired shape.

Whenever the fresh mortar is placed on the joints, it must be pressed hard to obtain a strong connection with the old internal mortar.

Care must be taken when using first-class ashlar or masonry. Otherwise, the mortar does not cover the edges of the face. The pointed surface is kept wet for at least a week or plowed after application.

Also Read: What Is Dressing of Stone | Types of Dressing of Stone

Types of Pointing:

Different types of pointing in construction are as follows.

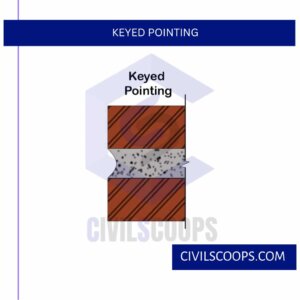

1. Keyed Pointing

In flush pointing, the mortar is pressed on the joints joined and finished with the face of the wall. While the pressed mortar is still green, a groove is formed, passing the folded end of a small steel bar (6 mm in diameter) straight along the centerline of the joints. Vertical joints are also finished in the same way.

2. Cut Pointing

In this type of pointing, the mortar is pressed first in joints. While the mortar is still green, the top of the horizontal joints is pressed from 3 to 6 mm with the pointing tool. Thus, the joint is finished by tilting from the top of the joint to the bottom.

3. Flush Pointing

In this type, the mortar is pressed hard on the joined joints and ends flush with the edge of the masonry units. The edges are well trimmed with a spatula and a straight edge.

It doesn’t look good. However, aiming the flush is more durable because it resists the provision of space for dust, water, etc. for this reason, this method is widely used.

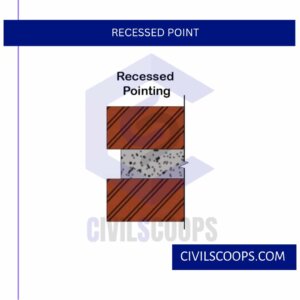

4. Recessed Point

In this case, the mortar is pressing 5 mm or more at the edges. During the placement of the mortar, the face of the sharpener is held vertically, using a suitable tool. This guy looks really good.

Useful Article for You

- How Wide Is a Cinder Block

- How Much Is a Coffered Ceiling

- How to Make Mortar

- How Long Does Hempcrete Last

- How to Use a Hand Sight Level

- How to Construction

- How to Build a Lean to Roof

- How Are Tunnels Built

- How to Layout a Building

- How Wide Is a Car Parking Space

- How Do Shear Walls Work

- How to Measure Concrete Slump

- How Are Bridge Foundations Built

- How to Use Washers with Screws

- How Dense Is Sand

- How High Is a Window from the Floor

- How to Fix Spalling Concrete Foundation

- How Does a Beam Bridge Work

- How Do They Pour Concrete Under Water

- How Does a Sewer System Work

- How High Are Countertops

- How to Seal Brick Wall Interior

- How to Resurface Cement

- How to Use Portland Cement

- How Is Plaster Made

- How to Find Fineness Modulus

- How to Get Rid of Spray Paint Smell on Metal

- How Many Types of Slope Are There

- How Big Is a Stair Landing

- How Does Rebar Help Concrete

- How to Identify a Load Bearing Wall

- How to Get Paint Off Concrete Without Chemicals

- How to Fix Water Damaged Drywall

- How Much to Get Septic Pumped

- How to Cut a Nail or Screw

- How Long Does Wet Concrete Take to Dry

- How Is Varnish Made

- How Does Ejector Pump Work

- How Does a Cantilever Bridge Work

- How Does Hydrometer Work

- How to Get Wet Blood Out of Carpet

- How to Build House on Slope

- How Thick Is Plaster Wall

- How Suspension Bridges Work

- How to Seal a Concrete Roof

- How Was Cement Invented

- How to Calculate Area of Steel

- How to Check Silt Content in Sand

- How a Building Is Constructed

- How Are Roads Classified in India

- How Many Types of Cement in India

- How to Find Contour Interval

- How to Stop Leakage from Ceiling

- How Hardness of Brick Is Tested

- How Many Types of Paint Brushes Are There

- How to Calculate Skirting Area

- How Many Types of Beam

- How to Make Road

- How Many Types of Chain in Surveying

- How to Calculate Weight of Steel Bar

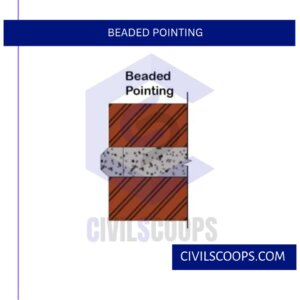

5. Beaded Pointing

Beaded pointing is formed by steel or ironed with a concave edge. It looks good but will damage easily when compared to other types.

6. Tuck Pointing

In this case, the mortar is pressed first at the anchored joint and finished with the face. While the pressed mortar is green, the channel or narrow channel is cut in the center of the channel, which is 5 mm wide and 3 mm deep.

This groove is then filled with white cement mass, projected beyond the face of the joint by 3 mm. If the projection is made in the mortar, it is called a pointing bastard or half-a-bend point.

Also Read: Mortar Vs Cement | Types of Cement | Types of Mortar

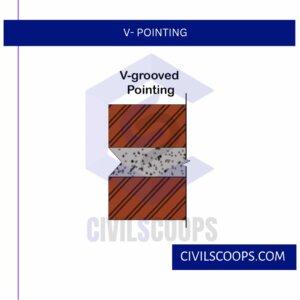

7. V- Pointing

Weathered pointing is done by making a V-shaped projection. Weathered Pointing. This is done by making a V-shaped projection.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Pointing?

pointing, in building maintenance, the technique of repairing mortar joints between bricks or other masonry elements. When aging mortar joints crack and disintegrate, the defective mortar is removed by hand or power tool and replaced with fresh mortar, preferably of the same composition as the original.

What Is Tuck Pointing?

Tuckpointing, sometimes referred to as repointing or brick pointing, is a process to finish or repair mortar joints between bricks or stones with a narrow ridge of lime putty or fine lime mortar.

What Cement to Use for Pointing?

Portland Cement

A typical mortar mix for Repointing purposes, for use in an area subject to normal weather conditions, would comprise 1 part Portland Cement, 1 part Lime and 5½ parts Sand.

Types of Pointing

- Weathered pointing

- Beaded pointing

- Recessed pointing

- Tuck pointing

- Struck pointing

Flush Pointing

Flush pointing is when mortar is pressed hard into the raked joints and finished off flush with the edge of masonry units. The edges are then neatly trimmed with a trowel and straight edge.

What Is Brick Tuck Pointing?

Tuckpointing (also called tuck pointing or tuck-pointing) is a way of using two contrasting colours of mortar in the mortar joints of brickwork, with one colour matching the bricks themselves to give an artificial impression that very fine joints have been made.

How Do You Do Pointing on Brick?

Hold the hawk below the brick, just under the area that will be repointed. With the pointing trowel, scoop up a small amount of mortar and press in the new mortar. As mortar drops down, mix it back into the original mound on the hawk and reuse it on the brick.

How to Do Pointing on a Brick Wall?

The surfaces to be pointed (existing bricks and mortar) must first be moistened to minimize loss of water in the mortar through capillary action. Next, the mortar must be pushed to the end of the cavity and firmly compressed, in fairly thin layers applied right after the previous layer hardens but before it dries.

V Pointing

V pointing is a technique similar to keyed pointing work. The process begins by filling and pressing mortar into the joint, ensuring a flush finish. The distinguishing feature of V pointing is the subsequent formation of a V-shaped groove within the joint.

What Material Is Used for Tuckpointing?

Portland cement

The cement used for tuckpointing and laying is a hydraulic cement, meaning it is water-resistant. Portland cement is available in shades of grey and white. 3.) And Mason’s Lime (Calcium Hydroxide / Type S Hydrated Lime / Slaked lime) is lime that has been treated with water.

What Type of Mortar Is Best Used for Tuckpointing?

Type N mortar

Type N mortar is a typical mix for tuckpointing and laying softer materials. It is not the strongest type of mortar, but it does provide some flexibility to homeowners who don’t require as much strength in their mortar for typical home construction projects.

What Type of Mortar Is Used for Tuckpointing?

Type n, o, and m mortars are the most commonly used today.

Keyed Pointing

Keyed pointing is a type of mortar joint that is pressed into the mortar with a pointed tool, which leaves a curved arc groove in the mortar. This type of pointing gives the wall an excellent exterior look. It is used especially for the best type of work for vertical joints of walls.

Cut Pointing

Recessed Point

Recessed pointing, sometimes referred to as raked joints, is when the mortar joint is raked back a certain depth from the face of the brick. The mortar is first made flush with the brick and then raked out to the desired depth.

Beaded Pointing

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Corian Countertops

- All About Repointing Brick

- All About Prismatic Compass Surveying

- What Is Scrap Value and Salvage Value

- Introduction of Gantry Girder | Load on Gantry Girder

[/su_note]

Originally posted 2023-10-25 12:09:03.