Difference Between Flexible Pavement and Rigid Pavement | What is Pavement | Types of Pavement

Table of Contents

What is Pavement?

Pavement or carriageway, often referred to as pavement meaning, is that part of the road or highway that supports the wheel loads imposed on it from traffic moving over it. Essentially, when one asks, ‘What is a pavement?‘, it refers to this supportive structure.

It ought to be strong enough to resist the stresses that are being developed as a result of traffic.

Pavement should also be thick enough to distribute the external loads on the earthen sub-grade so that sub-grade can safely bear these external loads.

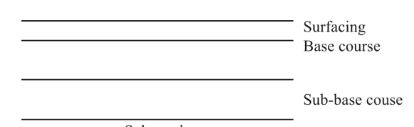

The pavement consists of a few layers of pavement materials over a prepared soil sub-grade

Pavement consists of one or more layers.

A simple classification of layers as per Indian practice is shown in as per below fig. no-1.

Sub Grade Fig No-1

The surfacing is the topmost layer, which should be smooth, abrasion-resistant, dustproof, and strong.

The base course immediately below the surfacing is a medium to distribute the stress evenly.

The sub-base course gives additional help in distributing the stress.

Sub-grade is the compacted earth below the sub-base course. Pavement should be even. It should have light-reflecting materials for night visibility.

The layer surfacing is the topmost layer, which should be smooth, abrasion-resistant, dustproof, and strong.

The base course immediately below the surfacing is the medium to distribute the stress evenly.

Sub-base the base course that gives additional help in distributing the stress. Sub-grade is the compacted earth below the sub-base course. Pavement should be even.

It should have light-reflecting materials for night visibility.

Based on location, materials of construction, and other factors, roads are classified into different types, including the flexible and rigid pavement.

The flexible and rigid pavement difference lies in their construction materials and behavior under load, such as earth road, gravel road, water-bound macadam (WBM) road, bituminous or blacktop road, and cement concrete road.

Also Read: What Is Camber in Road | Types of Camber | Advantages of Camber in Road

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is an Undercoat

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is the Standard Door Frame Size

- What Is a Spandrel Beam

- What Is a Fire Escape

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Pony Wall

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is Rafters

- What Is a Slab in Construction

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Inverted Beam

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Short Column

- What Is Sbc of Soil

- What Is Plum Concrete

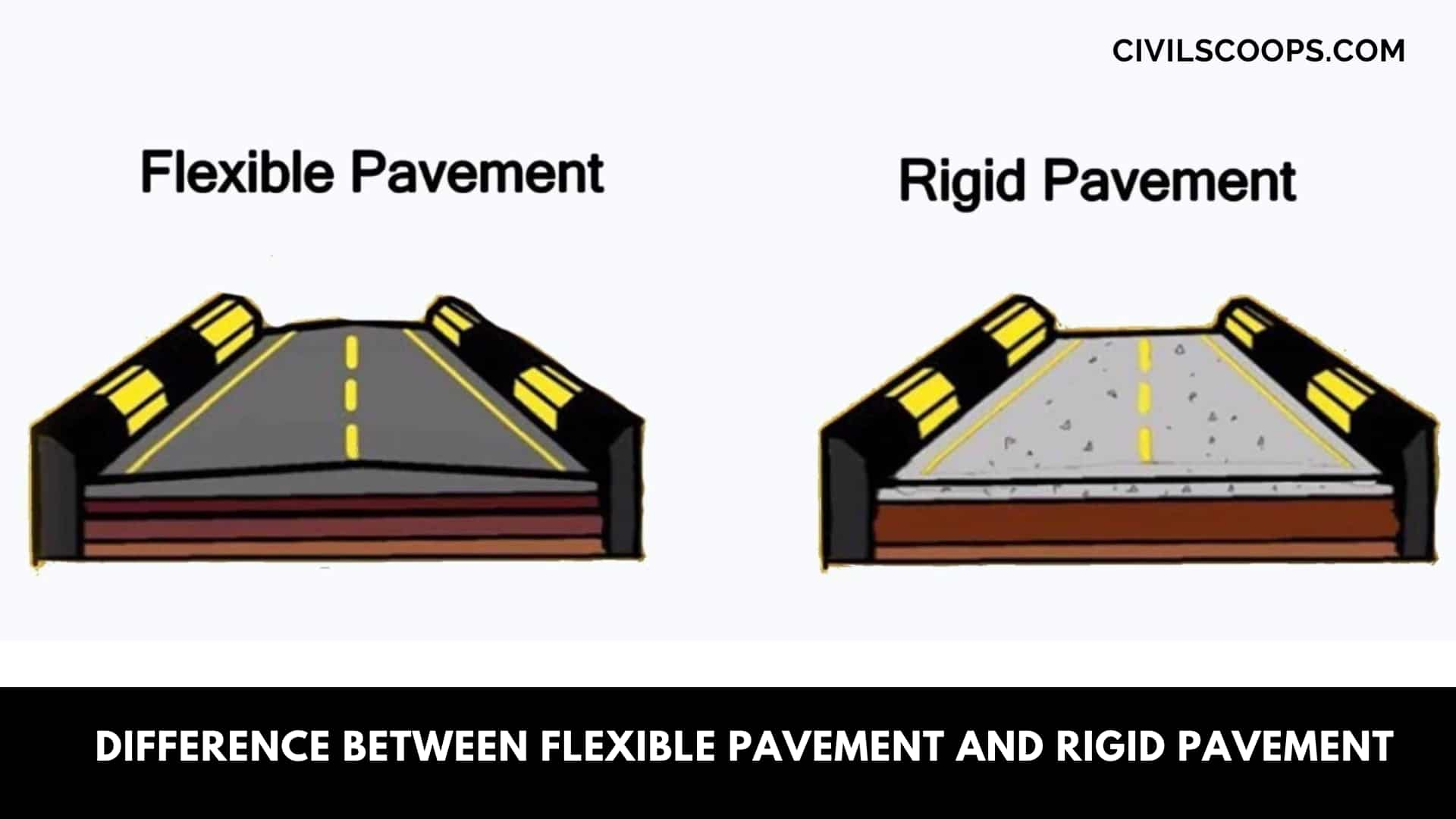

Types of Pavement

This is classified from the point of structural behavior as:

- Flexible Pavement

- Rigid Pavement

- Semi-rigid Pavement

- Composite Pavement

1. Flexible Pavement

Flexible pavements are Such, which on the whole have Minimal or Low flexural strength and Therefore are rather flexible at their structural action under the loads

The flexible pavement layers reflect this deformation of these lower layers on-to that the top layer of the layer.

Therefore, if the lower layer of the pavement or soil subgrade is undulated.

The flexible pavement surface also gets undulated. Flexible pavement consists of four components :

- Subgrade (Prepared Road Bed).

- Subbase Course.

- Base Course.

- Surface Course.

The flexible pavement layers transmit this vertical or compressive stresses to the lower layers by grain transfer through the points of contact at the granular structure.

A well-compacted granular structure consisting of strong graded aggregate (interlocked aggregate structure with or without binder materials) can move the compressive stresses through a wider area, and so forms a good flexible pavement layer This load spreading ability of this layer, therefore, depends on the type of the mix design and the materials factors.

Bituminous concrete is among the best flexible pavement layer materials Other materials that fall under the group arc, All granular materials without a bituminous binder, granular base, and sub-base course materials such as the Water Bound Macadam, crushed gravel, aggregate, soil-aggregate mixes, etc.

The vertical compressive Pressure is equal to the pavement surface directly under the wheel load and also is equivalent to the contact pressure under the wheel because of the ability to distribute the pressures to a larger area from the shape.

Of a truncated cone, the pressures decreased at the lower layer

Hence by taking full advantage of the Pressure distribution characteristics of the flexible pavement, the layer system concept has been developed,

According to this. The flexible pavement might be constructed in many layers, and the top layer was the strongest as the highest compressive stresses should be sustained by this layer, along with the tear and wear as a result of the traffic.

The lower layers have into take up only lesser magnitudes of stresses, and there’s not any direct wearing action because of traffic loads.

Therefore inferior materials with lower cost can be used in the lower layers.

The lowest layer is the prepared surface consisting of the local soil itself, called the subgrade.

A typical cross-section of a flexible pavement structure is shown in as per below fig. no-1; this consists of a wearing surface on top, below which is the base course followed with the subbase course and the lowest layer consists of the soil subgrade that has the lowest stability one of the four typical flexible pavement components.

Each of the flexible pavement layers above the subgrade, viz. sub-base, base course, and the surface course may consist of one or more layers of the same or slightly different materials and specifications.

Also Read: Alignment of Road | Alignment in Design | Horizontal Alignment of Road | Vertical Alignment of Road

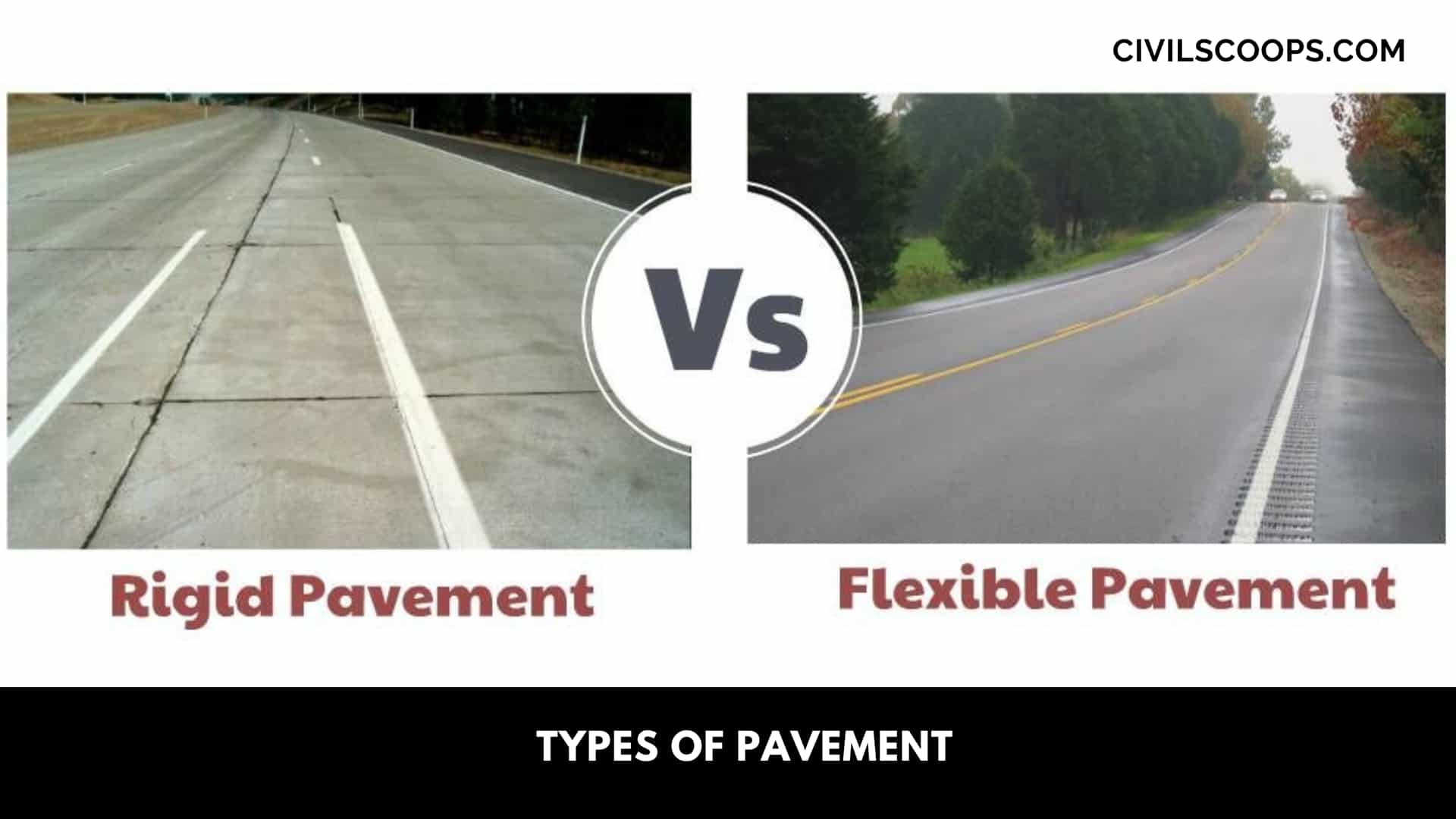

2. Rigid Pavement

Rigid pavements are those that possess noteworthy flexural strength or flexural rigidity. The flexible pavement and rigid pavement difference is evident in how they transfer pressures.

In rigid pavements, the pressures aren’t transferred from grain with the lower layers, as in the case of flexible pavement layers.

The rigid pavements are made with Portland cement concrete-either plain, reinforced or prestressed concrete the plain cement concrete slabs are expected to take-up roughly 40 kg/sq. Cm. Flexural stress.

The rigid pavement has the slab action and is capable of transmitting the wheel load stresses through a wider area below.

- The main point of difference in the structural behavior of rigid pavement compared to the flexible pavement is the critical condition of stress from the rigid pavement ist that the maximum flexural stress was occurring from the slab because of wheel load and the temperature changes where-as from the flexible pavement It’s the distribution of compressive stresses.

- Since the rigid pavement slab has tensile strength, tensile stresses are developed due to the bending of the slab under a wheel load and temperature variations.

- So the types of pressures developed and their distribution inside the concrete slab that is concrete are quite different.

- The rigid pavement doesn’t get deformed into the shape of the surface as it could bridge the minor variations of the lower layer.

- The cement concrete pavement slab may very well serve as a wearing surface in addition to an effective base course.

- Therefore generally, the rigid pavement structure is made up of cement slab that is concrete, below that the granular base or sub-base-course can be provided (see above fig. 2).

- Although the cement concrete slab may also be laid directly over the soil subgrade, this isn’t preferred, particularly when the subgrade, consists of fine-grained soil.

- Supplying a good base or sub-base course layer below the concrete slab that is concrete increases the pavement life considerably and thus works out more economical in the long run.

- The rigid pavements are often designed, along with the stresses are analyzed using the elastic theory and assuming the pavement within an elastic plate resting over a elastic or a viscous foundation.

3. Semi-Rigid Pavement

When bonded materials like the pozzolanic concrete, lean cement concrete, or soil-cement are used in the base course or sub-base course layer, the pavement layer has considerably higher flexural strength than the common flexible layers.

However, these bonded materials do not possess as much flexural strength as the cement concrete pavements.

Therefore when this intermediate class of materials is used in the base or sub-base course layer of the pavements are either designed on experience, or by using a new design approach.

These semi-rigid pavement materials have a low resistance to impact and abrasion and therefore are usually provided with flexible pavement surface course.

4. Composite Pavement

A composite pavement consists of multiple structurally significant layers of different heterogeneous compositions.

A typical example is a brick sandwiched concrete pavement.

The top and bottom layers are of cement concrete, which sandwiches a bricklayer in the neutral axis zone.

Useful Article for You

- How Wide Is a Cinder Block

- How Much Is a Coffered Ceiling

- How to Make Mortar

- How Long Does Hempcrete Last

- How to Use a Hand Sight Level

- How to Construction

- How to Build a Lean to Roof

- How Are Tunnels Built

- How to Layout a Building

- How Wide Is a Car Parking Space

- How Do Shear Walls Work

- How to Measure Concrete Slump

- How Are Bridge Foundations Built

- How to Use Washers with Screws

- How Dense Is Sand

- How High Is a Window from the Floor

- How to Fix Spalling Concrete Foundation

- How Does a Beam Bridge Work

- How Do They Pour Concrete Under Water

- How Does a Sewer System Work

- How High Are Countertops

- How to Seal Brick Wall Interior

- How to Resurface Cement

- How to Use Portland Cement

- How Is Plaster Made

- How to Find Fineness Modulus

- How to Get Rid of Spray Paint Smell on Metal

- How Many Types of Slope Are There

- How Big Is a Stair Landing

- How Does Rebar Help Concrete

- How to Identify a Load Bearing Wall

- How to Get Paint Off Concrete Without Chemicals

- How to Fix Water Damaged Drywall

- How Much to Get Septic Pumped

- How to Cut a Nail or Screw

- How Long Does Wet Concrete Take to Dry

- How Is Varnish Made

- How Does Ejector Pump Work

- How Does a Cantilever Bridge Work

- How Does Hydrometer Work

- How to Get Wet Blood Out of Carpet

- How to Build House on Slope

- How Thick Is Plaster Wall

- How Suspension Bridges Work

- How to Seal a Concrete Roof

- How Was Cement Invented

- How to Calculate Area of Steel

- How to Check Silt Content in Sand

- How a Building Is Constructed

- How Are Roads Classified in India

- How Many Types of Cement in India

- How to Find Contour Interval

- How to Stop Leakage from Ceiling

- How Hardness of Brick Is Tested

- How Many Types of Paint Brushes Are There

- How to Calculate Skirting Area

- How Many Types of Beam

- How to Make Road

- How Many Types of Chain in Surveying

- How to Calculate Weight of Steel Bar

- How to Find One Way and Two Way Slab

Difference Between Rigid Pavement and Flexible Pavement

- The rigid pavement vs flexible pavement design approach varies. Design of rigid pavement is based on scientific design stresses of concrete, whereas the flexible pavement vs rigid pavement design is mostly empirical in nature.

- Life of rigid pavement is more than the flexible one.

- Maintenance of well deigned rigid pavement is practically very small, whereas the bituminous surface of flexible pavement needs frequent maintenance.

- The initial cost of rigid pavement is much more than the flexible one. Considering the stage of construction, flexible pavement is preferred to the rigid pavement. The selection of a types of pavement depends on the availability of materials of construction.

- Surface characteristics play another role in the selection of a types of pavement. A good cement surface is smooth, free from potholes and corrugations. Flexible pavement does not possess the above facilities.

- An impervious layer of the pavement is essential for the sub-grade. Preference will always be the rigid pavement as concrete is impervious.

- Traffic dislocation during construction for about a month takes place as concrete requires a minimum of 28 days for curing and setting. Inflexible pavement traffic is allowed to move on the pavement once it is rolled.

Also Read: All About Turbidity of Water | What Is Turbidity of Water | Procedure of Turbidity of Water Test

Ideal Road Pavement Requirement

Here, We are seeing the list of ideal road pavement requirements are as follows.

- Ensure there is less noise when the vehicle is moving on it.

- The thickness must be required to distribute the wheel load pressure to a safe value on sub-grade soils,

- It must be structurally strong to withstand all kinds of stress imposed on it.

- To prevent skidding of vehicles, it must have a sufficient coefficient of friction.

- It should be dustproof so that there is no risk to traffic safety.

- It must provide impenetrable surfaces, so that sub-grade soils are well protected, and

- It offers low maintenance with long life.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Difference Between Flexible Pavement and Rigid Pavement

Types of pavement in road construction. There are two main types of road surfaces and pavement construction methods: rigid pavement (consisting of one layer) and flexible pavement (typically made up of multiple layers).

Flexible Pavement

Flexible pavement consists of a surface layer of bitumen-bound aggregate (asphalt concrete), several lower layers of appropriate quality aggregate and the subgrade beneath. The layers enable the pavement to “bend”, reducing damage and the need for repairs over time.

Rigid Pavement

Rigid pavements are constructed of portland cement concrete slabs resting on a prepared subbase of granular material or directly on a granular subgrade. Load is transmitted through the slabs to the underlying subgrade by flexure of the slabs.

What Are the Different Types of Pavements?

- Flexible pavement

- Full depth asphalt pavement

- Rigid pavement

- Concrete pavements

- Contained rock asphalt mat

Rigid Pavement Definition

Rigid pavements are constructed of portland cement concrete slabs resting on a prepared subbase of granular material or directly on a granular subgrade. Load is transmitted through the slabs to the underlying subgrade by flexure of the slabs. Flexible pavements are constructed of several thicknesses.

Rigid and Flexible Pavement

Flexible pavements generally require some sort of maintenance or rehabilitation every 10 to 15 years. Rigid pavements, on the other hand, can often serve 20 to 40 years with little or no maintenance or rehabilitation. Thus, it should come as no surprise that rigid pavements are often used in urban, high traffic areas.

What Is Composite Pavement?

A composite pavement structure is defined as a structure comprising two or more layers that combine different characteristics and that act as one composite material.

Semi Rigid Pavement

Semi rigid pavement is a composite multilayer pavement structure consisting of a porous asphalt concrete with porosity between 20 and 30% by volume of Marshall Mix design which is filled or flooded by a special formulated Portland cement mortar grouting material.

Pavement Resurfacing

Pavement resurfacing is renewing a road’s surface by applying a new layer of asphalt or concrete over the existing one, improving its condition and lifespan.

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Pointing

- Corian Countertops

- All About Repointing Brick

- What Is Scrap Value and Salvage Value

- Introduction of Gantry Girder | Load on Gantry Girder

[/su_note]

Originally posted 2023-10-27 11:46:16.