EPDM Flat Roof Installation | Cost of EPDM Flat Roof | How to Install EPDM Rubber Roof | EPDM Flat Roof Installation

Table of Contents

What Is EPDM?

EPDM, known for its epdm rubber roofing cost effectiveness, is an extremely durable synthetic rubber roofing membrane widely used in low-slope buildings in the United States and worldwide. Its two primary ingredients, ethylene and propylene, are derived from oil and natural gas.

What Is EPDM Roofing?

EPDM is a type of roofing material that is used for flat roofing systems. Homeowners may not choose it for aesthetic purposes, but it’s practical and durable, and it will certainly get the job done in terms of protecting your property from the elements. It can be used for both residential and commercial structures that have low slopes.

EPDM flat roofs are designed to last about 25-30 years. They are flexible, lightweight, and have fire resistance to wind, thermal shock, UV radiation, hail, extreme temperatures, and more.

If you are interested in EPDM roofing installation, please feel free to get in touch with our team of experts.

Also Read: Green Roofs and Living Walls: An Overview of Benefits and Installation

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is a Spandrel Beam

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Pony Wall

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is a Slab in Construction

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Plum Concrete

- What Is Shell Structure.

- What Is Lumber

- What Is the Strongest Foundation for a House

- What Is the Meaning of Soundness of Cement

- What Is Flyover Bridge

- What Is Under Reamed Pile

- What Is Weir

- What Is Inverted Beam

- What Are the Advantages of Levelling?

- What Is Sunk Slab

- What Is Brick Bat Coba

- What Is Isolated Footing

- What Is Long Column

- What Is Plate Load Test

- What Is Formwork

- What Is Concealed Beam

- What Is Acp

- What Is Wbm Road

- What Is Slab

- What Is Quick Setting Cement

- What Is Rapid Hardening Cement

- What Is Perennial Canal

- What Is Wpc Board

- What Is Grade of Cement

- What Is Culvert Bridge

- What Is Ferrocement

- What Is Mortar in Construction

- What Is Floating House

- What Is Combined Footing

- What Is Estimation?

- What Is the Si Unit of Weight

- What Is a Basement

- What Is Pert and Cpm

- What Is Rafter

- What Is Well Foundation

- What Is Design Period

- What Is Nominal Mix Concrete

- What Is Raft Footing

EPDM Flat Roof Installation

EPDM roofing installation is a very easy process and it is widely used nowadays. EPDM roofing is a type of roofing that is installed with large sheets.

The EPDM roofing process is a type of process which required fewer laborers and it does not require too much-skilled labor.

This type of method is a “fully adhered” method where an adhesive material is used to bond together. The EPDM roofing process is a step-by-step process that provides rubber roofing to protect your flat roof.

Some items that are required to install the EPDM rubber roofing are below,

- EPDM membrane

- Paint roller

- Adhesives (for bonding purposes)

- Utility knife or scissors

- Gloves and eye protection

- Push broom

Cost of EPDM Flat Roof

The rubber roofing cost, particularly for epdm roofing cost per square foot, varies from one range to another range because of the availability of raw materials and skilled laborers.

On a typical flat roof, the install cost of an EPDM flat roof is expected to vary from $6.50 to $12.50 per square foot. Or for the low slope roof replacement, it varies from $9750 to $18750 for 1500 square feet.

The flat roof cost also depends on the number of penetrations, the number of layers of insulation, also the existing roof removing cost, and the cost depending on tear-off may be lower or higher.

And Other costs affecting factors are accessibility, overall roof difficulty, and the location of the project. For this above reason, we can say this flat roof system also increases the total cost of the project.

How to Install EPDM Rubber Roofing?

The process of how to install epdm roofing, specifically epdm roof installation, is straightforward and it is widely used nowadays.

EPDM rubber roofing is a type of roofing that is installed with large sheets. EPDM rubber roofing process is a step-by-step process that provides rubber roofing to protect your flat roof.

This type of method is a “fully adhered” method where an adhesive material is used to bond together. There are have many steeps and required experience to avoid many mistakes that cause damage to the roof.

The steeps are showing below.

- Prepare the roof deck.

- Add a drip edge and drip batten.

- Install the rubber membrane.

- Apply the finishing touches.

1. Prepare the Roof Deck

At first, we have to prepare the roof deck by cleaning the deck from the grime or oil and also cleaning any sharp edges of OSB board or plywood from the roof deck.

The adhesive, can lead to a problem with the moisture with a little amount, for this reason at first you should be ensuring that everything is totally dry then you can start the installation process.

If over an existing roof you want to install EPDM then at first you should be cover it with a clean OSB board or sanded plywood to protect the membrane create a barrier and cover it.

For the roof decking if you want directly apply the EPDM then a layer of insulation should be added to prevent the water vapor problems.

2. Add a Drip Edge and Drip Batten

After ready the roof deck we will need to install a drip edge with the batten aligning the curved top.

Before installing the drip edge, into the fascia the drip batten is installed around the roof and into the gutter system to guide drain water extend the decking.

A drip edge and drip batten system can prevent erosion around the foundation.

3. Install the Rubber Membrane

To cover the roof edge and exterior walls completely with a thick overhang we will need enough EPDM membrane. After the drip edge is installed, the rubber membranes are unrolled in the place where they will be installed.

When you applied the rubber membrane to the bonding adhesive for up to half hours it will be relaxed in a place because when it is applied it will not create any problem.

4. Apply the Finishing Touches

The finishing touches may be small on the final edges, but care to do right and they take time. Around the edge of the border, the adhesive should be applied.

By using pressure-sensitive flashing the corners you will need to be sealed. For vents to create watertight seals use flashing and another roof preventing things.

To prevent the entry of moisture from the membrane all edge is the seal by the silicon sealant. After that by trimming you can remove the extra membrane from the roof.

Full Replacement or Over Boarding of a Roof Deck

When considering installing a flat roof membrane, especially for full replacement or over-boarding of a roof deck at first, we have to choose the right contractor from the local area. After that, we have to know about the contractor, his experience and skill to improve the quality of your roof.

After choosing an experienced contractor you have to select the materials for your roof construction. For the increasing lifespan of your roof, you should be chosen quality material for the construction.

The materials are asphalt composition shingles, wood shakes, slate, metal, composition slate, and tile. After choosing and buying one material above them, we have to remove the old roof shingles from the roof. After removing the old shingles, we have to place new shingles on the place of the old roof.

If you create a wood deck then firstly you have to inspect the wood properly. After placing new roof materials drip edge is installed and the roof surface is ready.

Flat Roof Membrane Installation

The rubber flat roof installation process, a key aspect of flat roof membrane installation, is quite simple and it is widely used nowadays.

The flat roofing membrane process is a step-by-step process that provides rubber roofing to protect your flat roof. This type of method is a “fully adhered” method where an adhesive material is used to bond together.

There are have many steeps and required experience to avoid many mistakes that cause damage to the roof. The steeps are showing below-

- Roof preparation.

- Fitting and attaching the membrane.

- Finishing up.

1. Roof Preparation

At first, we have to prepare the roof by cleaning the deck from the grime or oil and also cleaning any sharp edges of OSB board or plywood from the roof deck.

The adhesive, can lead to a problem with the moisture with a little amount, for this reason at first you should be ensuring that everything is totally dry then you can start the installation process.

2. Fitting and Attaching the Membrane

After the preparation of the roof, the membrane should be fitting and attached to the roof. To cover the roof edge and exterior walls completely with a thick overhang we will need enough membrane. After the drip edge is installed, the membranes are unrolled in the place where they will be installed.

How to Fitting EPDM Membrane?

For fitting the EPDM membrane properly on the roof, it should be trimmed at the required. After that according to the required roof dimension trimmed the membrane and installed it on the roof.

Before installing the membrane on the roof, you have to ensure that the cutting part of the membrane did not cut too large or too short. In this way, you can fit the EPDM membrane on your roof.

How to Cutting EPDM Membrane?

For the EPDM membrane cutting, experts are essential because it is a lightly complicated process in roofing systems.

At first, you have to measure your home roof perfectly by a contractor or an expert after finishing the complete measurement of the roof you should be cutting the EPDM membrane on the measured roof dimension.

Before installing the membrane on the roof, you have to ensure that the cutting part of the membrane did not cut too large or too short. It is a basic fundament of the cutting of EPDM membrane for your roof.

Useful Article for You

- How Wide Is a Cinder Block

- How Much Is a Coffered Ceiling

- How to Make Mortar

- How Long Does Hempcrete Last

- How to Use a Hand Sight Level

- How to Build a Lean to Roof

- How Are Tunnels Built

- How to Layout a Building

- How Wide Is a Car Parking Space

- How Do Shear Walls Work

- How to Measure Concrete Slump

- How to Use Washers with Screws

- How Dense Is Sand

- How High Is a Window from the Floor

- How Does a Beam Bridge Work

- How Do They Pour Concrete Under Water

- How Does a Sewer System Work

- How High Are Countertops

- How to Seal Brick Wall Interior

- How to Resurface Cement

- How to Use Portland Cement

- How Is Plaster Made

- How Many Types of Slope Are There

- How Big Is a Stair Landing

- How to Get Paint Off Concrete Without Chemicals

- How to Fix Water Damaged Drywall

- How Much to Get Septic Pumped

- How to Cut a Nail or Screw

- How Long Does Wet Concrete Take to Dry

- How Is Varnish Made

- How Does Ejector Pump Work

- How Does Hydrometer Work

- How to Get Wet Blood Out of Carpet

- How to Build House on Slope

- How Thick Is Plaster Wall

- How Suspension Bridges Work

- How to Seal a Concrete Roof

- How Was Cement Invented

- How to Calculate Area of Steel

- How to Check Silt Content in Sand

- How a Building Is Constructed

- How Are Roads Classified in India

- How Many Types of Cement in India

- How to Find Contour Interval

- How Hardness of Brick Is Tested

- How Many Types of Paint Brushes Are There

- How to Calculate Skirting Area

- How Many Types of Beam

- How Many Types of Chain in Surveying

- How to Find One Way and Two Way Slab

- How Many Types of Houses

- How to Find Steel Bar Weight

- How to Calculate Septic Tank Capacity in Liters

- How to Calculate the Bearing Capacity of Soil

- How Many Types of Bricks Are There

- How Many Types of Cement Are There

- How to Make Block

- How Many Types of Bridge

- How Much Sand Required for 1 Sq.feet Area

- How to Texture Walls with Paint

- How Many Type of Beam

- How Is Tar Made

- How to Stop Water Leakage from Terrace

- 1cum How Many Bricks

- How to Calculate Shear Force and Bending Moment

- How to Building

- How to Calculate Fineness Modulus

- How to Find Zero Force Members in a Truss

- How to Calculate Scrap Value

- How False Ceiling Is Done

- How Many Types of Footing

- How to Calculate Steps in Staircase

Gluing Down the EPDM Rubber

At first, we have to place the cutting pieces of EPDM rubber on the roof after placing the cutting piece of EPDM, the glue is brushed over the pieces.

After glue brush over the rubber cutting pieces, the pieces are fixed on the roof by a temporary load or a temporary clip. After 2 or 3 days when the glue is dry, the temporary load or clip is removed from the roof.

By following some steps, the EPDM rubber is glued down.

Also Read: WPC Board Vs Plywood | Which Should Be a Better Choice | What Is WPC Board | What Is Plywood

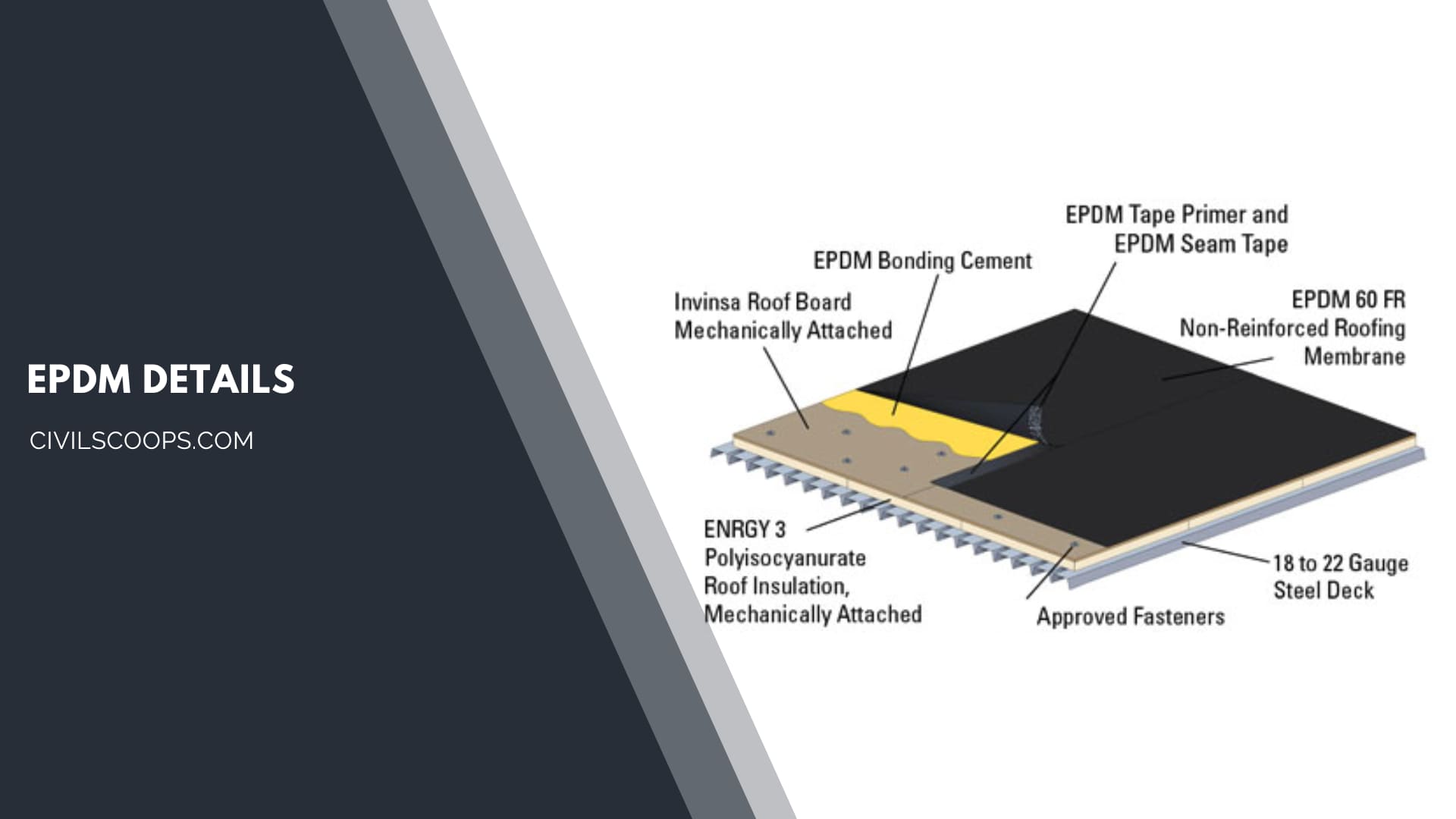

EPDM Details

Given the rubber flat roof cost and durability, EPDM is widely used worldwide, including in the United States in roof constructions. EPDM is a roofing membrane that is manufactured with extremely durable synthetic rubber and used on low slope buildings in many countries.

The EPDM has two primary ingredients one is propylene and another is ethylene that’s are derived from natural gas and oil. The EPDM is available in markets in two colors one is white and another is black.

And also, it is available in the market in many lengths that’s start from 7.5 feet to 50 feet and there are have only two types of thickness that are 45 mm and 60 mm.

EPDM rubber roofing process is the step-by-step process that provides rubber roofing to protect your flat roof. For installed EPDM we have to follow some steps properly that’s are below.

1. Roof Preparation

At first, we have to prepare the roof by cleaning the deck from the grime or oil and also cleaning any sharp edges of OSB board or plywood from the roof deck.

The adhesive, can lead to a problem with the moisture with a little amount, for this reason at first you should be ensuring that everything is totally dry then you can start the installation process.

2. Fitting and Attaching the Membrane

After the preparation of the roof, the membrane should be fitting and attached to the roof. To cover the roof edge and exterior walls completely with a thick overhang we will need enough membrane. After the drip edge is installed, the membranes are unrolled in a place where they will be installed.

3. Apply the Finishing Touches

The finishing touches may be small on the final edges, but care to do right and they take time. Around the edge of the border, the adhesive should be applied.

By using pressure-sensitive flashing the corners you will need to be sealed. For vents to create watertight seals use flashing and another roof preventing things.

To prevent the entry of moisture from the membrane all edge is the seal by the silicon sealant. After that by trimming you can remove the extra membrane from the roof.

Epdm Roof Trims

Depending on the installation of EPDM on the roof the trims are divided into four types. The types are under tiles, flat roofs, at a parapet, and up a wall, the EPDM roof trims can be done.

You measure the roof and fix the membrane on the measured roof and the extra part is trimming. After that trimming, you can remove the extra membrane from the roof.

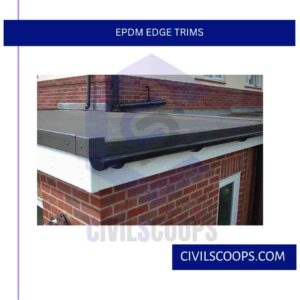

EPDM Edge Trims

In EPDM roofing edges are totally and perfectly trimmed by flexible rubber. EPDM edge trims help the edges from wear and tear, it also resists it from ozone. Here, the edges will be curved types to do extra protection.

Epdm Drip Trims

EPDM drip is a metallic or wooden bar that is fixed at the edges of the roof and the middle of the roof, At first, one series of bars is placed; then the rubber roofing is provided and finally second series of those bars is provided. Those bars are fixed with nails.

Epdm Flashing

EPDM flashing is a rubber tape that is placed over the rubber roofing. It is installed to provide extra support and stability.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Epdm Flat Roof Installation

EPDM (ethylene propylene diene terpolymer) is a synthetic rubber black membrane commonly used in commercial and medical facilities. But like I said earlier, even though it’s used mostly in commercial, EPDM roofing has its place in residential roofing. (EPDM on flat portion of an asphalt shingle roof)

What Is Epdm?

EPDM rubber is a type of synthetic rubber that is used in many applications. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene, dicyclopentadiene, and vinyl norbornene. 4-8% of these monomers are typically used.

What Is Epdm Roofing?

EPDM is an extremely durable synthetic rubber roofing membrane (ethylene propylene diene terpolymer) widely used in low-slope buildings in the United States and worldwide. Its two primary ingredients, ethylene and propylene, are derived from oil and natural gas.

What Is Epdm Rubber?

Natural rubber, as its name implies, is made using natural plant-based materials that give its excellent chemical and physical properties, but because EPDM rubber is a synthetic material, it will retain better properties as well as being an overall stronger material.

What Is Epdm Rubber Roofing?

Epdm is a rubber roofing membrane that is extremely durable and long-lasting. Epdm stands for ethylene propylene diene terpolymer, with the primary two ingredients being ethylene and propylene. The epdm rubber membrane is a synthetic rubber that is used in a number of applications because of the advantages it offers.

What Is Epdm Roofing Material?

EPDM roofing membranes are available in large sheets, typically black, although white versions are also available to reflect sunlight and reduce heat absorption. These sheets are either fully adhered, mechanically fastened, or ballasted onto the roof substrate.

What Is a Rubber Membrane Roof?

Membrane roofing is a type of roofing system for buildings, RV’s, Ponds and in some cases tanks. It is used to create a watertight covering to protect the interior of a building. Membrane roofs are most commonly made from synthetic rubber, thermoplastic (PVC or similar material), or modified bitumen.

Epdm What Does It Stand for?

Ethylene propylene diene monomer, or EPDM, is a type of synthetic rubber that is commonly used across many industries. Developed in the early 1960s, it is made from ethylene, propylene, and diene monomers and is a very versatile and durable type of rubber with many applications.

Cost of Epdm Flat Roof

EPDM is a durable and affordable low-pitch roofing option. EPDM material costs can range from $3 to $12 per square foot but are usually around $4 to $6.50. The cost of EPDM installation adds another $1.50 to $3 per square foot. For a 1,500 square foot roof, expect to pay between $8,000 and $22,000.

How to Install Epdm Rubber Roofing?

- Roof Deck Preparation. Clean the roof surface prior to installation.

- Install Drip Batten. Install the Drip batten wherever a gutter is present.

- Install Drip Back Drip Trim. The Drip Trim has a front and back piece.

- Chase out Wall Upstand.

- Relax Rubber Membrane.

Flat Roof Membrane Installation

Flat roof membrane installation involves preparing the roof deck, applying flashing and edging, installing the membrane (EPDM, TPO, PVC), sealing seams or welding (if necessary), detailing around penetrations, and conducting post-installation inspections for a watertight and durable roofing system. Professional expertise and adherence to manufacturer guidelines are crucial for a successful installation.

How to Install Membrane Roofing?

- Prepare the roof surface.

- Apply flashing and edging.

- Install the membrane, securing it per manufacturer instructions.

- Seal seams or weld for watertight connections (if applicable).

- Detail around edges and penetrations.

How Long Does an Epdm Roof Last?

50 years

An EPDM rubber roof is incredibly long-lasting and durable. The rubber recycled and used for the synthetic rubber membrane isn’t damaged under the sun’s UV or ultraviolet rays. If installed correctly, you can expect a rubber roof to in excess of up to 50 years.

How Long Do Rubber Roofs Last?

If installed correctly, you can expect a rubber roof to in excess of up to 50 years. Because an EPDM flat roof is compromised of durable rubber, it can withstand extreme weather conditions such as hail or snow and common weather such as rain and strong winds.

What Is the Best Glue for Epdm Rubber?

For gluing EPDM, the only product to use is DP5/3. This is a single component, solvent free adhesive, designed specifically for gluing EPDM to itself and a wide range of metals such as aluminium, stainless steel and anodized steel & plastics such as ABS & PVC.

What Is Epdm Membrane?

EPDM is essentially a synthetic rubber, making it an extremely durable roofing solution. The membrane has high resistance to UV radiation and remains flexible even at low temperatures. EPDM Is not inherently fire resistant, however, some membranes offer variations that are fire retardant.

How Is Epdm Roofing Installed?

The insulation must first be mechanically fastened or adhered to the deck to install an EPDM roof. Next, the EPDM membrane is bonded over the insulation using adhesives and seam tapes. Almost every roof is a good candidate for an adhered EPDM system thanks to its flexibility and light weight.

How to Apply Epdm Roofing?

- Prepare the roof surface.

- Install flashing and edging.

- Roll out and adhere the EPDM membrane using recommended adhesives or tapes.

- Seal seams and edges as per manufacturer instructions.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Metal Ceilings: Types and Features

- Financial Ratios Used in Construction Business

- Applications of Controlled Low-Strength Materials (CLSM)

- Effects of Unrepaired Early-age Cracking in Concrete Structures

- Compressive Strength of Concrete: What Causes Low-Strength Breaks in Concrete Cylinders?

[/su_note]

Originally posted 2023-12-06 09:53:39.