What Is Scaffolding | Types of Scaffolding

Table of Contents

What Is Scaffolding?

Scaffolding is a temporary platform used to lift, support, and supply materials during a construction process for the repair or cleaning of a structure.

It is installed before construction or maintenance work begins. Therefore, whatever the size of a building, scaffolding will always be necessary.

This is done to ensure the safety of workers while the building is being maintained or constructed. In addition, it also provides some degree of support for a standing structure during the construction phase.

Scaffolding is made of wood or steel. It must be stable and strong to support workers and other construction materials placed on it.

Types of Scaffolding Used in Construction

The following are the types of scaffolding under construction:

- Simple scaffolding

- Double scaffolding

- Cantilever scaffolding

- Suspended scaffolding

- Trestle Scaffolding

- Steel scaffolding

- Patented scaffolding

- Wooden Gantries Scaffolding

Parts of Scafloding as Below Fig.

- Standards: The vertical posts (also called uprights)

- Ledgers: The horizontal members parallel to the wall

- Braces: The bracing system

- Putlogs: Horizontal members normal to the wall

- Transoms: Putlogs whose both ends are supported on ledgers in double scaffoldings

- Bridle: Member used to bridge openings (see the description of single scaffolding below)

- Boarding: Planks on which workmen stand

- Guard rail: Rail provided at about I m level to guard the men working on the boarding

- Toe board: Boards placed parallel to boarding near the wall to give protection to workers

- Base plate or sole plate. Plates on the ground supporting standards

Also Read: Skeleton Frame | Building Skeleton | Steel Structural Building

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is a Spandrel Beam

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Plum Concrete

- What Is Shell Structure.

- What Is Lumber

- What Is the Strongest Foundation for a House

- What Is the Meaning of Soundness of Cement

- What Is Flyover Bridge

- What Is Under Reamed Pile

- What Is Weir

- What Is Inverted Beam

- What Are the Advantages of Levelling?

- What Is Sunk Slab

- What Is Brick Bat Coba

- What Is Isolated Footing

- What Is Long Column

- What Is Plate Load Test

- What Is Formwork

- What Is Concealed Beam

- What Is Acp

- What Is Wbm Road

- What Is Slab

- What Is Quick Setting Cement

- What Is Rapid Hardening Cement

- What Is Perennial Canal

- What Is Wpc Board

- What Is Grade of Cement

- What Is Culvert Bridge

- What Is Ferrocement

- What Is Mortar in Construction

- What Is Floating House

- What Is Combined Footing

- What Is Estimation?

- What Is the Si Unit of Weight

- What Is a Basement

- What Is Pert and Cpm

- What Is Rafter

- What Is Well Foundation

- What Is Design Period

- What Is Nominal Mix Concrete

- What Is Raft Footing

- What Is Sill Height

- What Is Whole Circle Bearing

- What Is Consistency of Cement

- What Is an Arch

1. Single Scaffolding

This is being cheap, and it is most commonly used in the construction brickwork.

This type of scaffolding is mostly used for brickwork and consists of an outer row of verticals (called standards) to which longitudinal members are tied at different levels of working (see above fig.).

This type of scaffolding moot of members except platforms is usually made of bamboos and standards which are driven into the ground at a distance 1.5m to 2.0 m apart and about 1.2 m away from the wall to be constructed.

The cross members (putlogs) are tied to the standards at the outer end and rest on the walls being built inside. The platform is carried on the putlogs.

If the putlog level coincides with an opening in the wall, it cannot be placed on the wall. Hence it should rest on a cross piece (called bridle tube) tied at the wall end of the adjacent putlogs.

Cross bracing in the vertical planes between the verticals are also to be introduced for lateral stability.

Where the verticals posts cannot be placed on base plates or in holes made in the ground, it should be suitably placed and braced for lateral stability.

A popular method in such cases is to place the vertical post in a steel barrel of 60 cm in height and of suitable diameter filled with compacted earth as shown above fig.

2. Double Scaffolding

This type of scaffolding is stronger than the single scaffolding and is used in the construction of stonework some times in addition to the diagonal braless. Inclined supports called reacting source, are provided to prevent the slipping of scaffold away from the wall.

Also Read: How to Optimize Load Distribution for Bends and Shear Walls

3. Cantilever Scaffolding

It is a type of scaffolding in which the patterns are supported on a series of needles, and these needles are removed through holes in the wall. This is called a single frame type scaffolding.

In the other type, the needles are supported inside the floor through the openings, and this is called independent or double frame scaffolding. Care must be taken when building scaffolding on a cantilever.

Generally, cantilever scaffolding is used in conditions such as

- When the terrain is unable to support standards,

- When the floor near the wall is free of traffic,

- When the top of the wall is under construction.

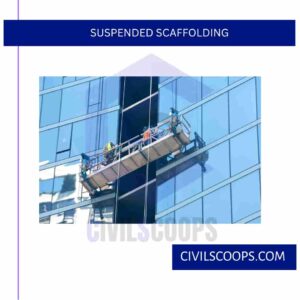

4. Suspended Scaffolding

This type of scaffolding is suitable for hight steel frame construction as well as for mailer works such as painting distend peering etc.

In suspended scaffolding, the work platform is suspended from the roofs with the help of cables or chains, etc., it can be raised or lowered to the required level. This type of scaffold is used for repairs, notes, paintings, etc.

5. Trestle Scaffolding

This type of platform supported on the top of Mohole device such as a tripod, radar. This scaffolding is suitable for minimum or repair works.

In trestle scaffolding, the work platform is supported on tripods or mobile ladders. It is generally used for work inside the room, such as paintings, repairs, etc. up to a height of 5m.

6. Steel Scaffolding

The construction details of steel scaffolding are the same as of timber scaffolding except for wooden members and replaced by steel tubes is about 40 mm to 60 mm, and the thickness of steel metal is about 5 mm.

Steel scaffolding is constructed by steel tubes that are attached by couplers or steel fittings. It is very easy to build or dismantle.

It has greater resistance, greater durability, and greater resistance to fire. It is not economical, but it will give workers more security. Therefore, it is widely used today.

7. Patented Scaffolding

Patented scaffolding is made of steel, but is equipped with special couplings and structures, etc., are ready scaffolding available on the market.

This type of work platform for scaffolding is placed on supports that can be adjusted to the required level.

8. Wooden Gantries Scaffolding

In construction operation where structural materials are beyond the capacity of manual handing, the gantries are used.

Also Read: Design and Construction of Submerged Floating Tunnel

Useful Article for You

- How Wide Is a Cinder Block

- How Much Is a Coffered Ceiling

- How to Make Mortar

- How Long Does Hempcrete Last

- How to Use a Hand Sight Level

- How to Build a Lean to Roof

- How Are Tunnels Built

- How to Layout a Building

- How Wide Is a Car Parking Space

- How Do Shear Walls Work

- How to Measure Concrete Slump

- How to Use Washers with Screws

- How Dense Is Sand

- How High Is a Window from the Floor

- How Does a Beam Bridge Work

- How Do They Pour Concrete Under Water

- How Does a Sewer System Work

- How High Are Countertops

- How to Seal Brick Wall Interior

- How to Resurface Cement

- How to Use Portland Cement

- How Is Plaster Made

- How Many Types of Slope Are There

- How Big Is a Stair Landing

- How to Get Paint Off Concrete Without Chemicals

- How to Fix Water Damaged Drywall

- How Much to Get Septic Pumped

- How to Cut a Nail or Screw

- How Long Does Wet Concrete Take to Dry

- How Is Varnish Made

- How Does Ejector Pump Work

- How Does Hydrometer Work

- How to Get Wet Blood Out of Carpet

- How to Build House on Slope

- How Thick Is Plaster Wall

- How Suspension Bridges Work

- How to Seal a Concrete Roof

- How Was Cement Invented

- How to Calculate Area of Steel

- How to Check Silt Content in Sand

- How a Building Is Constructed

- How Are Roads Classified in India

- How Many Types of Cement in India

- How to Find Contour Interval

- How Hardness of Brick Is Tested

- How Many Types of Paint Brushes Are There

- How to Calculate Skirting Area

- How Many Types of Beam

- How Many Types of Chain in Surveying

- How to Find One Way and Two Way Slab

- How Many Types of Houses

- How to Find Steel Bar Weight

- How to Calculate Septic Tank Capacity in Liters

- How to Calculate the Bearing Capacity of Soil

- How Many Types of Bricks Are There

- How Many Types of Cement Are There

- How to Make Block

- How Many Types of Bridge

- How Much Sand Required for 1 Sq.feet Area

- How to Texture Walls with Paint

- How Many Type of Beam

- How Is Tar Made

- How to Stop Water Leakage from Terrace

- 1cum How Many Bricks

- How to Calculate Shear Force and Bending Moment

- How to Building

- How to Calculate Fineness Modulus

- How to Find Zero Force Members in a Truss

- How to Calculate Scrap Value

- How False Ceiling Is Done

- How Many Types of Footing

- How to Calculate Steps in Staircase

- How to Calculate Silt Content in Sand

- How Many Types of Foundation Are There Based on Depth

Below Are Three Main Reasons Why the Construction Industry Uses Scaffolding:

1. Ensures security

Safety is a priority at construction sites; the use of scaffolding, therefore, becomes important to create a safe workplace for workers working at heights during the construction of a building.

Another advantage of using scaffolding is that it provides a flat and balanced work platform that allows multiple employees to work at one location simultaneously.

This really helps in the quick construction of different structures. Maintaining balance for workers is easier with scaffolding equipment; therefore, the chances of unjustified accidents decrease.

Scaffolding also requires handrails on the upper platform, reducing the chance of injury. This is also important for the safety of pedestrians and the public.

2. Easy access

The construction of skyscrapers is a difficult task because many parts of a building are difficult to reach for workers due to their position.

Scaffolding solves this big problem, and workers can concentrate on their work without any difficulty. They can reach any part of a building’s wall or ceiling at an arm’s length.

As a small wooden, fiberglass, or light metal platform, it offers the necessary height to complete a task easily and efficiently.

3. Position Advantage

A major advantage of scaffolding is the strategic position it provides workers. Although ladders are also used for this purpose, they are angled and do not provide a solid platform for the balance of workers.

Scaffolding places workers directly in front of the parts of the wall or ceiling where they need to work. This gives them a big advantage.

If multiple workers are required to work side by side simultaneously, this is not possible using the ladders summary.

So far, it should be clear that scaffolding is a necessary part of the construction industry, whether it is about building skyscrapers or carrying out repairs and maintenance on any structure.

The scaffolding not only guarantees a faster completion of the works but also guarantees the safety of the workers and the public in the construction sites.

Also Read: All About Pony Wall | What Is a Pony Wall | Uses of Pony Wall | Pros and Cons of Pony Wall

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Scaffolding?

Scaffolding, also called scaffold or staging, is a temporary structure used to support a work crew and materials to aid in the construction, maintenance and repair of buildings, bridges and all other human-made structures.

Types of Scaffolding Used in Construction

- Double scaffolding

- Patented scaffolding

- Kwikstage scaffolding

- Frame scaffolding

- Tubular scaffolding

What Is Scaffolding Used For?

Scaffolding is widely used during construction and renovation activities. In its simplest form, a scaffold is any temporary elevated or suspended work surface used to support workers and/or materials. There are many types of scaffolds, both supported and suspended.

What Is Scaffolding Safety?

Scaffolding safety is a combination of practices and safety procedures that enforces proper and safe use of scaffoldings. It involves a set of preemptive actions in building, inspecting, using, and tagging scaffolds.

What Is Scaffolding Made Of?

Scaffolding is a temporary structure that is typically made from metal poles and wood planks and used to support construction workers, inspectors, cleaners, and others who need to work at height.

What Does It Cost to Rent Scaffolding?

Generally, prices for scaffold rentals may range between $15 and $50 per day or between $40 and $150 per week. Ask your scaffolding provider whether the rates are per piece or per an entire scaffolding kit.

How Many Types of Scaffolding?

- Double scaffolding

- Trestle scaffolding

- Kwikstage scaffolding

- Frame scaffolding

- Mobile scaffolding

Cantilever Scaffolding

Cantilever scaffolding, also known as needle scaffolding, is a type of scaffolding that is a separate scaffold that is built to angle out from a structure. Usually, this scaffolding is situated near balconies for easy access.

the Purpose of Scaffolding Is to

scaffold, in building construction, temporary platform used to elevate and support workers and materials during the construction, repair, or cleaning of a structure or machine; it consists of one or more planks of convenient size and length, with various methods of support, depending on the form and use.

What Are the 3 Types of Scaffolds?

- Suspended Scaffolds.

- Supported Scaffolds.

- Aerial Lifts.

Types of Suspended Scaffolding

- Catenary.

- Float (ship)

- Interior Hung.

- Multi-level.

- Multi-point Adjustable.

What Are Examples of Scaffolding?

- Suspended scaffolding

- Cantilever scaffolding

- Single scaffolding

- Patented scaffolding

- Double scaffolding

- Steel Scaffolding

What Does Scaffolding Look Like?

Scaffolding is a temporary structure that is typically made from metal poles and wood planks and used to support construction workers, inspectors, cleaners, and others who need to work at height. [Note: This article is about scaffolding as it relates to industrial work.

What Is a Cantilever Scaffold?

A cantilever scaffold is a type of scaffold system commonly used in construction and maintenance work to provide a platform for workers, tools, and materials at elevated heights. It consists of a structure that extends horizontally beyond its support, allowing access to areas that might be otherwise challenging to reach.

What Is Trestle Scaffolding?

A trestle scaffold is a scaffold assembled from prefabricated trestles, braces and accessories. Trestle scaffolds, for example ‘A-frame’ (see Figure 2) and ‘H-frame’ trestle scaffolds, are commonly used by bricklayers, plasterers and painters and for general fit-out and finishing work.

What Is Steel Scaffolding?

Steel scaffolding is scaffold products and accessories, materials that are made of steel structures, steel plates, steel pipes, and steel fittings. It is a type of scaffolding that sturdy with high load capacity, easy erection with standard sizes, and durable with long life.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- All About Construct Open Wells

- All About Severity of Concrete Cracks

- All About Pile Integrity Test Methods

- All About Underground Water Sources

- All About Construct a Concrete Building

[/su_note]

Originally posted 2023-12-09 11:01:15.