What Is Slip Form? | Slip Form Construction | Slip Form Technique| Types of Slip Form System

Table of Contents

What Is Slip Formwork?

Formwork is a temporary moulid that is used for the pouring of concrete. The Traditional formwork is made from timber, steel, glass fiber, and some other types of materials.

Slip Formwork, also known as slipform shuttering, is a special type of formwork and it is one of the advanced techniques which is carried out for rapid construction of megastructures mega structures such as the construction of chimneys, towers, silos, road construction as well as Bridge construction.

The word ‘Slip formwork’ itself indicates the meaning that it is formwork, or slip form work, that moves from its position for the construction of the structures.

Slip Form, a key aspect of slipform technology, is an advanced construction Technique in which the formwork continuously rises in the vertical direction for the construction process.

Slip Formwork, often utilized in slip form construction details, is used for the vertical construction of the RCC structures.

The Slip Formwork is an economical method that required very less labor because all the process in this technique mostly runs automatically.

Slip Forming, embodying the slip forming technique, is an economical, fast, and accurate form of construction Technique that is used for the construction of various types of high-rise structures.

History of Slip Formwork

The Slip Formwork Technique was discovered in the year 1910 by America for the construction of elevators, cooling towers chimneys, etc.

The slipform method of construction was first used in the construction of the Skylon tower near Niagara Falls, Ontario in the year 1965.

The Sheraton Waikiki Hotel in Hawaii was also constructed from the Slip formwork Technique in the year 1969.

The United States Kingdom adopted the technique of the slip formwork for the construction of roadways, curbs, and bridges, etc.

The slipform formwork Technique is also used for the construction of the paving of airports and runways.

Also Read: All About Formwork Failure | What Is Formwork Failure | Causes of Formwork Failure

Useful Article for You

- What Is a Highway Flyover

- What Is Grouting

- What Is a Pile Cap

- What Is a Bond Beam in Masonry

- What Is Sapwood

- What Is Crane

- What Is a Gable

- What Is Superelevation

- What Is Kerb

- What Is the Purpose of Washers

- What Is the Size of a Brick in Inches

- What Is Reinforced Masonry

- What Is Workability

- What Is Bond Breaker

- What Is Plasticizer in Concrete

- What Is Luminous Flux Vs Lumens

- What Is Caisson

- What Is a Benchmark Surveying

- What Is Bracing in Construction

- What Is a Beam in Construction

- What Is a Spandrel Beam

- What Is a Weep Hole

- What Is Tie Beam

- What Is Fine Aggregate

- What Is Flag Stone

- What Is Development Length

- What Is Cement Plaster

- What Is a Pitched Roof

- What Is a Monolithic Slab

- What Is Linear Distance

- What Is Shovel

- What Is Lintel in Construction

- What Is a Concept Sketch

- What Is Mezzanine Floor

- What Is Man Sand

- What Is Plaster Made Out of

- What Is a Floating Slab

- What Is Falsework

- What Is Bituminous

- What Is a Spillway

- What Is Curb and Gutter

- What Is Dampness

- What Is Lap Length

- What Is the Full Form of Fsi

- What Is Door Frame

- What Is Plinth Protection

- What Is Traffic Rotary

- What Is Grade Slab

- What Is Rolling Margin of Steel

- What Is Modulus of Rupture

- What Is Fresh Concrete

- What Is Dpc in Construction

- What Is Earthen Dam

- What Is Plum Concrete

- What Is Shell Structure.

- What Is Lumber

- What Is the Strongest Foundation for a House

- What Is the Meaning of Soundness of Cement

- What Is Flyover Bridge

- What Is Under Reamed Pile

- What Is Weir

- What Is Inverted Beam

- What Are the Advantages of Levelling?

- What Is Sunk Slab

- What Is Brick Bat Coba

- What Is Isolated Footing

- What Is Long Column

- What Is Plate Load Test

- What Is Formwork

- What Is Concealed Beam

- What Is Acp

- What Is Wbm Road

- What Is Slab

- What Is Quick Setting Cement

- What Is Rapid Hardening Cement

- What Is Perennial Canal

- What Is Wpc Board

- What Is Grade of Cement

- What Is Culvert Bridge

- What Is Ferrocement

- What Is Mortar in Construction

- What Is Floating House

- What Is Combined Footing

- What Is Estimation?

- What Is the Si Unit of Weight

- What Is a Basement

- What Is Pert and Cpm

- What Is Rafter

- What Is Well Foundation

- What Is Design Period

- What Is Nominal Mix Concrete

- What Is Raft Footing

- What Is Sill Height

- What Is Whole Circle Bearing

- What Is Consistency of Cement

- What Is an Arch

- What Is a Frost Wall

- What Is a Tremie

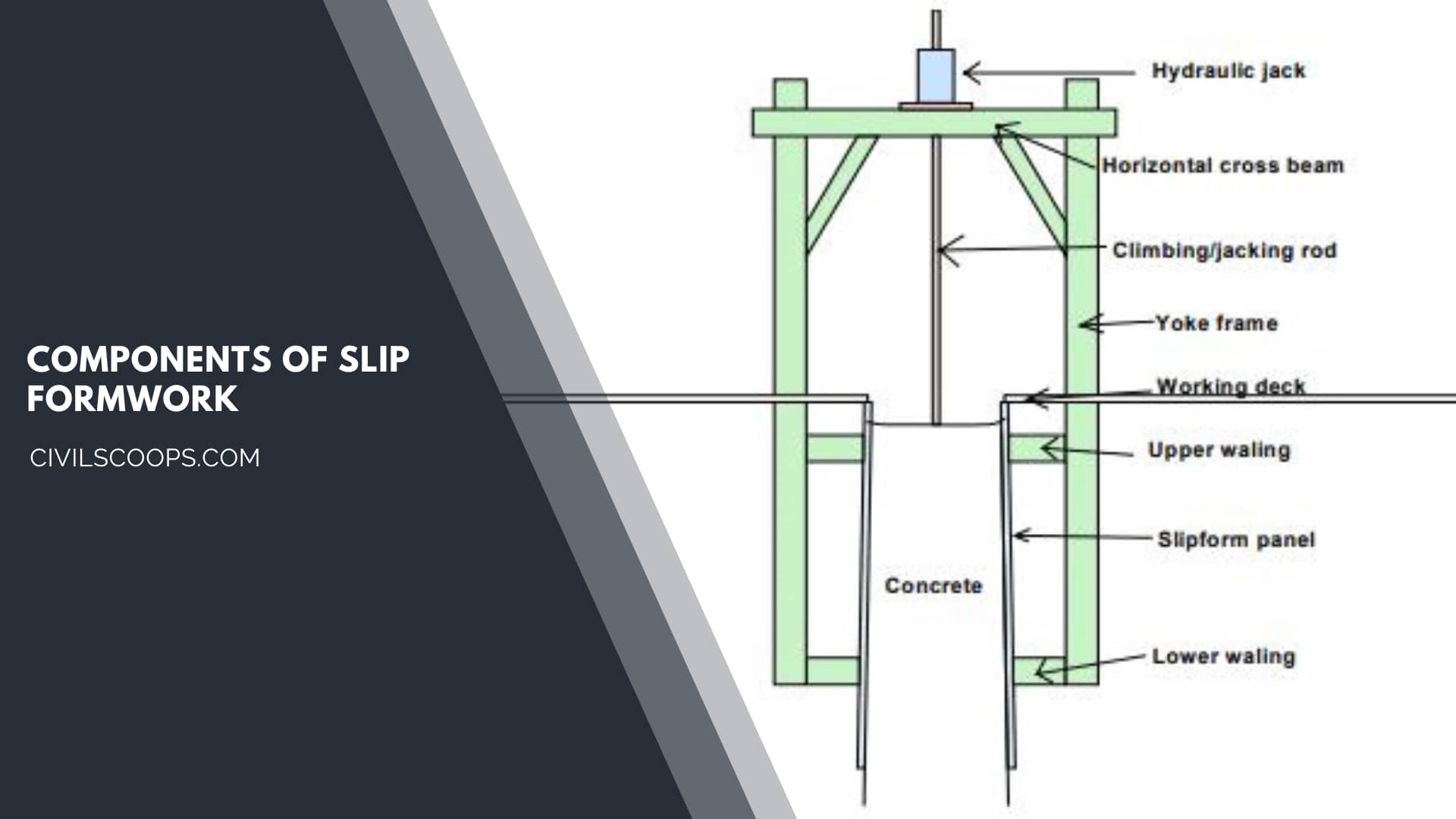

Components of Slip Formwork

Various parts of the slip formwork, integral to slip forming construction, are as follows

- Slip Form Ribs

- Yokes

- Working platform or Deck

- Suspended scaffolding

- Lifting jacks

The Yokes in the slip forms are used to attach and support wales at regular intervals with the legs.

The Yokes are capable of transmitting the lifting forces from the jacks that are used during the removal of the formwork.

It also plays the function of resisting the lateral force of the plastic concrete within the formwork. The Lifting jacks are mounted on the jack rods that are used to lift the slip form.

Also Read: Carbon Concrete: Production and Advantages

Types of Slip Form System

The Slip form system is categorized into different types that are as follows

1. Cantilever Jump Form Method

In the cantilever jump Form method, the work of the lifting devices to lift and expand the formwork is done with the help of the electric motors.

This method minimizes the use of the cranes as it is attached to the large area of the formwork concerning the story height.

2. Vertical Slip Form System

In the vertical slip form system, the concrete form is surrounded by the platform which is used by the workers to stand and work safely. The concrete form and working platform are raised with the help of hydraulic jacks.

There are different types of hydraulic lifters are available that are used to efficiently lift the formwork for the whole horizontal projection.

3. Egg Shape Slip Form Method

The egg shape slip form method is based on the principle of the jump form that can be adapted to any geometric shape.

In this method, the circumference gets changed and the cantilever plate on the periphery is removed or extended.

The adjustment of the curvature can be done in this method by simply adjusting the circumferential slope and the axis.

The Egg shape slip form system is very flexible to accommodate the adjustment on each side of the wall as well as the products of the optimal working conditions.

4. Horizontal Slip Forming

In the case of the horizontal slip forming for the construction of the pavement and traffic separation walls are laid down.

The vibration and proper compaction are done and then the slip slowly moves ahead. This method is mostly used and suitable for the construction of Highways.

5. Conical Slip Formwork Method

The conical formwork system consists of the formwork having conical shapes that are made from the cantilever plates as well as the overlapping plates. These plates are attached through the steel yoke frames.

The Cantilever and the overlapping plates have the mechanism of automatic adjustment of the geometry.

It is one of the special types of the slip formwork method which is used for the construction of varying thickness walls.

Slip Form Technique

- In the Slip Formwork Technique, the slip forms raised and lifted in the upward direction at a rate of about 300 mm per hour.

- It supports itself on the core and does not require any kind of external support.

- The Slip Formwork mainly consists of three platforms is Top, middle, and bottom.

- The Topmost part of the slip formwork acts as a storage and distribution area, the middle platform of the slip formwork is located at the top of the area from which the concrete is poured.

- The Bottom platform of the slip form is used for the finishing work of the structure.

- It provides an Integrated scaffolding platform which consists of horizontal work platforms that provide safe working space to the workers as well as engineers and supervisors.

Also Read: All About Construct a Concrete Building

Slip Form Construction

- The Slip Formwork construction Technique is carried out for the construction of structures having a height of more than 16m.

- The slip form consists of the wall-shaped form which is approximately 1m to 2m high at the base of the structure.

- The slip formwork has a belt of forms in one for each surface. The slip forms rest on the internal as well as external surfaces of the walls.

- The Slip form construction helps to achieve the rate of construction of about 2m to 7.2m per day which is not possible with the help of the traditional method of formwork.

Useful Article for You

- How Wide Is a Cinder Block

- How Much Is a Coffered Ceiling

- How to Make Mortar

- How Long Does Hempcrete Last

- How to Use a Hand Sight Level

- How to Build a Lean to Roof

- How Are Tunnels Built

- How to Layout a Building

- How Wide Is a Car Parking Space

- How Do Shear Walls Work

- How to Measure Concrete Slump

- How to Use Washers with Screws

- How Dense Is Sand

- How Does a Beam Bridge Work

- How Do They Pour Concrete Under Water

- How Does a Sewer System Work

- How High Are Countertops

- How to Seal Brick Wall Interior

- How to Resurface Cement

- How to Use Portland Cement

- How Is Plaster Made

- How Many Types of Slope Are There

- How Big Is a Stair Landing

- How to Get Paint Off Concrete Without Chemicals

- How to Fix Water Damaged Drywall

- How Much to Get Septic Pumped

- How to Cut a Nail or Screw

- How Long Does Wet Concrete Take to Dry

- How Is Varnish Made

- How Does Ejector Pump Work

- How Does Hydrometer Work

- How to Get Wet Blood Out of Carpet

- How to Build House on Slope

- How Thick Is Plaster Wall

- How Suspension Bridges Work

- How to Seal a Concrete Roof

- How Was Cement Invented

- How to Calculate Area of Steel

- How to Check Silt Content in Sand

- How a Building Is Constructed

- How Are Roads Classified in India

- How Many Types of Cement in India

- How to Find Contour Interval

- How Hardness of Brick Is Tested

- How Many Types of Paint Brushes Are There

- How to Calculate Skirting Area

- How Many Types of Beam

- How Many Types of Chain in Surveying

- How to Find One Way and Two Way Slab

- How Many Types of Houses

- How to Find Steel Bar Weight

- How to Calculate Septic Tank Capacity in Liters

- How to Calculate the Bearing Capacity of Soil

- How Many Types of Bricks Are There

- How Many Types of Cement Are There

- How to Make Block

- How Many Types of Bridge

- How Much Sand Required for 1 Sq.feet Area

- How to Texture Walls with Paint

- How Many Type of Beam

- How Is Tar Made

- How to Stop Water Leakage from Terrace

- 1cum How Many Bricks

- How to Calculate Shear Force and Bending Moment

- How to Building

- How to Calculate Fineness Modulus

- How to Find Zero Force Members in a Truss

- How to Calculate Scrap Value

- How False Ceiling Is Done

- How Many Types of Footing

- How to Calculate Steps in Staircase

- How to Calculate Silt Content in Sand

- How Many Types of Foundation Are There Based on Depth

- How Does a Cantilever Bridge Work

- How to Tell If a Wall Is Load Bearing Single Story

Advantages of Slip Form Construction

There are various benefits of slip-form construction that are as follows

- The Slip-form construction is the economical method for the construction of high-rise structures.

- It requires less labor for its construction which ultimately saves labor costs.

- Better finished surface achieved and does not require plastering.

- The Slip Formwork does not require a crane to move it in an upward direction.

- Slip formwork helps to achieve high production rates.

- It provides more safety to the workers and proper working space so that the labor can work efficiently.

Disadvantages of Slip Form Construction

There are also some disadvantages of slip formwork that are as follows

- It takes a little more time for the arrangement of the various components.

- For the operation of the slip formwork, Expert supervision is needed.

- The stocking of the materials on the construction site is difficult.

- The Slip form requires more initial investment as compared to the traditional formwork.

- The operation must be continued under any weather conditions.

- The labors were required to train for a certain period with the advanced equipment and types of machinery before executing the work.

- Good coordination is required among the site organization for rapid construction.

- There will be more flexibility in the construction of the tapering structures

- The slip formwork allows the high speed of erection due to which there is faster completion of the construction project.

- The uniformity of the wall sections and the smooth, even surface can be achieved.

- It allows construction companies to increase the rate of construction and work productivity and complete the project within the stipulated time.

Applications of Slip Form Construction

Slip form is used for the construction of various types of structures which are as follows.

- Construction of chimneys

- Construction of silos

- Construction of shaft linings and surge shafts.

- Construction of the long-span bridges.

- It is also used in the construction of the lifts and stair shafts

- The slip forms are also used in the construction of the roads.

Safety Features of Slip Form Construction

The Safety features of the slip formwork are as follows

- The working platforms, ladders, guard rails, and windshields should be built into the completed system.

- The complete assembly of the slip formwork should be strong and should sustain the load of the persons working on it.

- There should be lateral support of forms provided.

- Care should be taken that all parts of the formwork should be moved at a uniform rate.

- It is necessary to check and ensure that there is any jam in the jack.

- The site engineers should have knowledge and skills in the health and safety management of these job sites.

Economical Consideration of Slip Form Construction

Here are some of the points that should be considered for the economic construction of the structures.

- The slip formwork is only economical for the construction of structures having a height of more than 16m.

- The thickness of the wall that is constructed should be a of minimum 15 cm.

- The slip-form system is only suitable for the construction of structures such as cooling towers, chimneys, piers tall buildings, etc.

Conclusion of Slip form Construction

The slip Form construction method is one of the innovative methods that is used for the construction of megastructures and it also helps to improve the productivity of the work as well as saves time required for the construction.

It helps construction businesses to deliver quality construction within the stipulated time of the project. This method ensures the quality control and homogeneity of the structure.

The slip-form method ensures quality construction, economical construction, and speedier construction.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Slip Form?

Slip forming, continuous poured, continuously formed, or slipform construction is a construction method in which concrete is poured into a continuously moving form. Slip forming is used for tall structures, as well as horizontal structures, such as roadways.

Slip Form Construction

Slipform is a construction method for reinforced concrete walls, generally lift and stair core walls, and is often economical for buildings more than ten storeys in height. Slipform construction involves the formwork for the walls being raised in a continuous process as the wall concrete is poured.

Slip Form Technique

Slip forming, continuous poured, continuously formed, or slipform construction is a construction method in which concrete is poured into a continuously moving form. Slip forming is used for tall structures (such as bridges, towers, buildings, and dams), as well as horizontal structures, such as roadways.

Horizontal Slip Form Construction

Horizontal slipforming is the on-site process of constructing continuous concrete elements. It involves concrete being poured into continuously moving plant. This is then vibrated and extruded from the specially designed attached formwork mould to produce the required profile.

Vertical Slip Form Construction

Slipforming is a technique for rapid construction of tall concrete structures, it involves the extrusion of the concrete in situ rather than casting in short lifts.

Horizontal Slip Forming

Horizontal slip forming, also known as continuous slip forming or simply slip forming, is a construction technique used to create continuous, seamless concrete structures. It involves a continuously moving formwork into which concrete is poured, allowing for the uninterrupted formation of structures like walls, curbs, barriers, and sometimes even towers or cores of high-rise buildings.

What Is Slip Form Construction?

Slip form construction is a continuous construction method used primarily for concrete structures. It involves a movable formwork system that enables the continuous pouring, shaping, and vertical movement of concrete to create tall structures like towers, cores of high-rise buildings, chimneys, silos, and other vertical elements.

Disadvantages of Slip Form Construction

- Minimal flexibility for changes once slipform concrete has commenced.

- Often requires additional steel temporary bracing to be provided to ensure cast core walls are structurally adequate until the slabs are constructed.

Slip Form Construction Details

The slipform process involves the continuous upward movement of formwork by means of jack rods and hydraulic jacks. The slipform system is a hydraulically operated formwork system. Hydraulic jacks are mounted on strategically located steel yoking frames to lift the formwork as the concrete is poured into the forms.

Slip Forming Concrete

Slip form concrete is a method of construction in which concrete is poured into the top of a continuously moving shallow form. As the concrete is poured, the formwork is raised vertically at a speed which allows the concrete to harden before it is free from the formwork at the bottom.

Slip Forming

Slip forming is a construction technique used to create continuous, seamless concrete structures. It involves a continuously moving formwork into which concrete is poured, allowing for the uninterrupted formation of various structures such as walls, cores of high-rise buildings, bridge piers, silos, and more.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- All about Hydraulic Trailer Technology

- All about of Working of Digital Theodolite

- New 3D-Printed Structural Concrete Footbridge in Paris

- What are As-Built Drawings and Why are they Important?

- Telematics: A Unique Fleet Management Solution for Construction Sector

[/su_note]

Originally posted 2023-12-11 10:35:47.